Coil Packing Solutions

Automatic Coil Packing Solution

The new steel coil packing line equipment for packing strip coils after cutting on the slitting-and-shearing line in the existing rolling-extrusion shop.

The packing system including coil down-ender, automatic wrapping machinery,coil strapping machine and automatic stocking system, automatic pallet strapping machine that connected by conveyor for automatic packing.

FHOPE provides a tailored coil packing system designed to enhance packaging processes and management. Our versatile system integrates seamlessly with various equipment like slitting lines, coil downenders, cranes, and more. We also offer a specialized system for hot mill coil packing, ensuring maximum efficiency. When connected with the ERP system, it significantly reduces labor costs for tasks such as scanning, strapping, and packing, and improves overall product management.

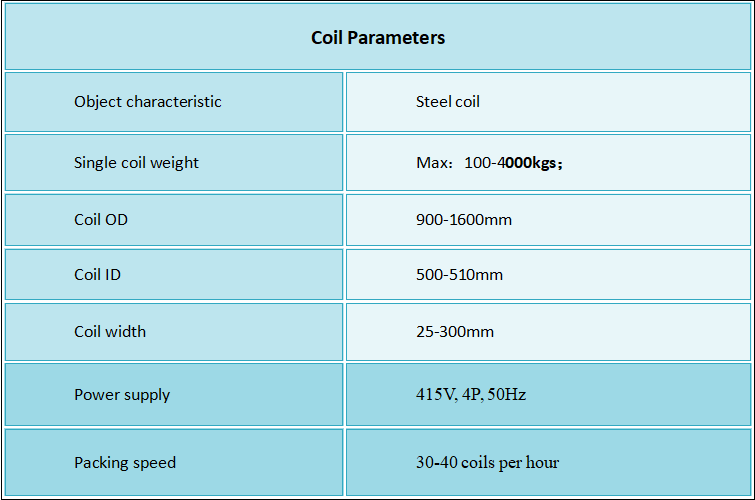

Automatic coil packing line designed per following steel coil:

A. SLIT COIL HANDLING AND STACKING LINE

Automatic Coil

Handling

Increasing the handling speed

Specifications

01 Automatic PLC grogram control

An automated Programmable Logic Controller (PLC) takes the reins, making operations smoother and more accurate by cutting down on manual errors.

02 Automatic separating the coil on turnstile.

No need for manual sorting here – the system is capable of separating each coil on its own. This neat feature speeds up the process and keeps things moving along nicely.

03 Strong structure for heavy loading.

This isn’t a lightweight system. It’s built sturdy and strong, able to handle heavy loads.

04 One time picking up one coil

Precision is key in coil handling. This feature ensures that the system picks up one coil at a time, reducing the chance of mishaps and potential damage to the coil.

05 Lifting nose with hydraulic driving.

Smooth and precise lifting? Check. The hydraulic drive makes sure that the lifting nose operates smoothly and accurately, so you know your coils are in safe hands.

The solution for making the coil handling and packing in a pipe line

Providing Customized Solution per different Loads

The handling solution primarily focuses on lifting the coil from the coil car and transferring it into the stacking machine, serving as an alternative to traditional cranes or fork lifters.

B. SLIT COIL WRAPPING AND STACKING LINE

The solution to help you have a fast return on investment.

FHOPEPACK

Steel Coil Wrapping

Stacking line

Specifications

01 Technical date:

| Min slit coil width that can be downended: | 15mm |

| Linear motion slides/wheels/camrollers | Linear |

| Lift powered by | Hydraulic |

| Tilt powered by | Hydraulic |

| Cycle time to down-end (1) coil | 20-30sec |

| Conveyor length | 1600mm |

| Conveyor Motor | app. 0.75Kw |

| Hydraulic supplier | 140 bar |

02 Conveyor:

Roller Conveyor Covered with PU

The PU covering makes sure your coils keep on rolling without a hitch, ensuring a smooth journey from start to finish.

Automatic Positioning for Picking Up Different Width Coils

No matter the width of your coil, the system automatically positions itself for pick-up. It’s like having an intuitive assistant that knows exactly where to be.

Strong Structure for Heavy Loading

This system is a real workhorse. Its robust structure can bear heavy loads, making it a reliable partner for those high-volume, heavy-duty operations.

Automatic slitting coils packing solution with prefect ROI

Offering Tailored Solutions for Various Loads

The idea behind the coil packing line is to integrate the coil strapping machine and packing machinery for enhanced automation. The machine applies compact layers of packing materials across all surfaces of the coil.

C. SLIT COIL PACKAGING

STRAPPING LINE

Explore our comprehensive range of solutions by choosing the areas that best suit your needs.

From Automated coil packaging lines, through coil wrapping machinery to relevant packaging materials, Fhope provides a diverse array of packaging equipment covering a wide spectrum for coil objects.

Leading manufacturer

Coil Packing System

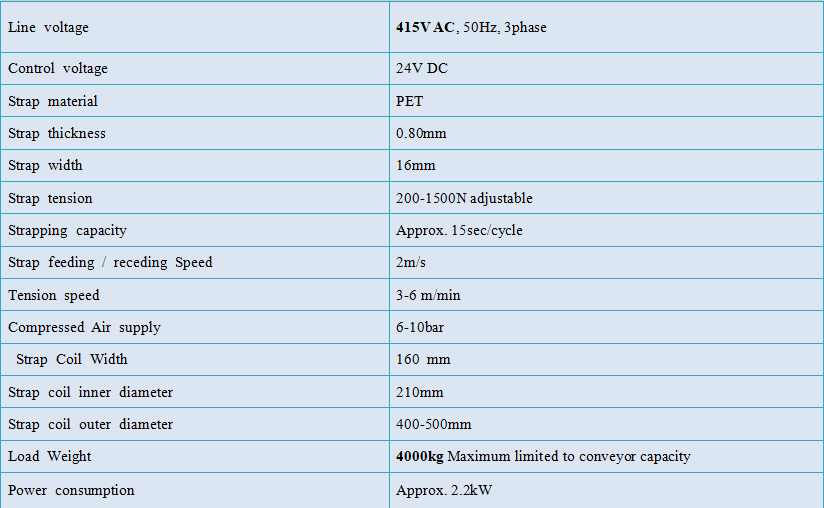

Specifications

Technical date:

Features:

- Strapping head at the top side.

- Ability to strap with PET strapping without parts change.

- Superior Electrical/Electronic Design including Siemens PLC control

- High performance strapping head with indexing mechanism, head moves on linear bearings toward load side, electric motion through direct rack/pinion, and load detection sensor.

- Internal potentiometer allow for adjustment of the strap tension

- A electric cabinet is possible for the operator to perform the movements in manual mode or in automatic mode.

- Model designing strapping head for easy change and maintain.

- Powerful motor with high drawing force

The solution for making the coil handling and packing in a pipe line

Offering Tailored Solutions for Various Loads

If you’re unsure about the functions needed in a coil packaging line, the following solution diagram can guide you to understand the typical requirements of a slitting center. Alongside strapping and wrapping, there are stations for weighing, labeling, coil centering, and automatic timber feeding…

More Special Solutions Can Be Option For Coil Packing Line

Vertical coil packing line, Economic coil packing system,auxiliary equipment very from projects

By Machine

Choose your preferred machine type and discover the solution that suits your needs best. Rest assured, the functionality of the coil packing line can be tailored to your specifications.

By Industry

Dig into solutions that match your specific industry or market segment. Whether it’s copper or aluminum, we’ve got your coil packaging needs covered.

More FHOPE Coil Packing Mchine….