If you’re in the industrial sector and looking for an efficient solution to shrink-wrap your products, then you’ve come to the right place. In this YouTube video, we will introduce you to the amazing world of Industrial Shrinking Machines. These machines are designed to streamline your packaging process and ensure that your products are securely wrapped and ready for shipment. So, let’s dive into the details and discover how these machines can revolutionize your packaging operations.

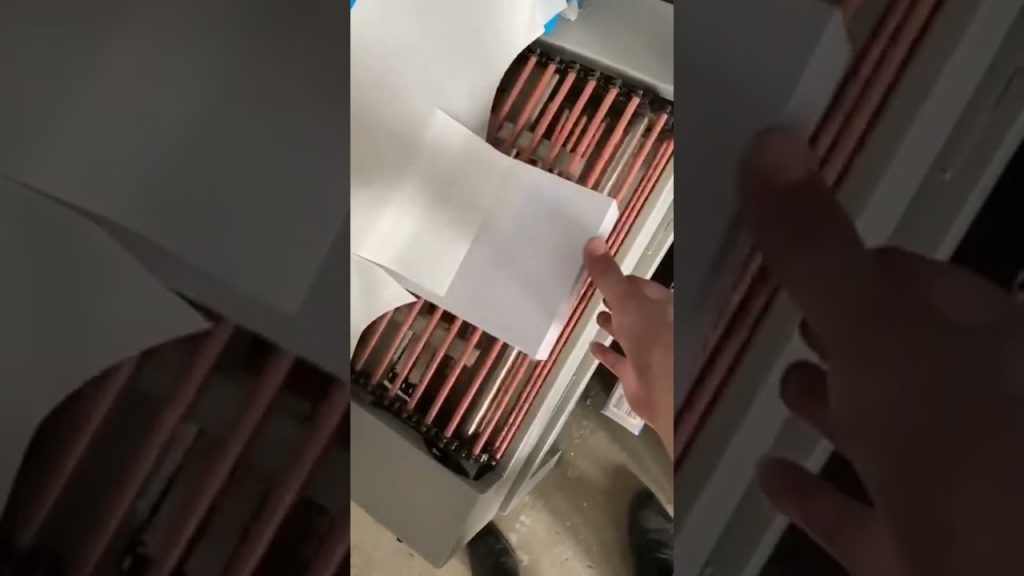

Industrial Shrinking Machines, also known as Heat Shrink Machines, are widely used in various industries such as food and beverage, pharmaceuticals, electronics, and logistics. These machines utilize heat to shrink a plastic film tightly around a product, creating a secure and tamper-proof packaging.

One of the most popular Industrial Shrinking Machines is the Part 24 Shrinking Machine. This machine is equipped with advanced features that automate the entire packaging process. It can handle a wide range of product sizes and shapes, making it suitable for diverse industries. The Part 24 Shrinking Machine ensures consistent and professional packaging results, enhancing the visual appeal of your products.

Another essential machine in the packaging industry is the Straightening Machine. This machine is used to straighten bent or deformed products, ensuring that they meet the required quality standards. By using a Straightening Machine, manufacturers can eliminate product defects and improve the overall quality of their products.

In addition to the Part 24 Shrinking Machine and the Straightening Machine, there is also a professional raw square pipe bending machine. This machine is specifically designed for bending square pipes accurately and efficiently. It is widely used in industries such as construction, automotive, and furniture manufacturing. By using a professional raw square pipe bending machine, manufacturers can achieve precise bending angles and ensure the structural integrity of their products.

Now that we have explored the various machines used in the packaging industry, let’s take a closer look at the benefits of using Industrial Shrinking Machines. Firstly, these machines significantly reduce packaging time, allowing manufacturers to increase their production capacity. With the automation features of Industrial Shrinking Machines, the packaging process becomes faster and more efficient.

Secondly, Industrial Shrinking Machines ensure consistent and high-quality packaging results. This not only enhances the visual appeal of your products but also provides protection against dust, moisture, and tampering during transportation. By investing in Industrial Shrinking Machines, manufacturers can guarantee the integrity of their products and enhance customer satisfaction.

Furthermore, Industrial Shrinking Machines are cost-effective in the long run. With their high efficiency and automation features, these machines eliminate the need for manual labor, reducing labor costs and minimizing human error. Additionally, the use of shrink film reduces packaging material costs compared to traditional packaging methods.

In conclusion, Industrial Shrinking Machines are a game-changer in the packaging industry. They streamline the packaging process, ensure consistent and high-quality results, and offer cost-effective solutions. If you’re looking to upgrade your packaging operations and improve your product presentation, Industrial Shrinking Machines are the way to go.

Check out our YouTube video for a detailed demonstration of Industrial Shrinking Machines and their benefits. Don’t miss out on the opportunity to revolutionize your packaging process. Invest in Industrial Shrinking Machines today for a professional and efficient packaging solution.

Check the coil packing solution with a leading manufacturer for the professional solution just here: Shrinking Machine

“Innovative Industrial Solutions: Advanced Machinery for Shaping, Bending, and Shrinking Pipes with Precision”