Check out the leading manufacturer for professional coil packing solutions here:

Title: Unveiling the Future of Automatic Stretch Wrapping: Lantech’s Patented Metered Film Delivery Technology

Introduction:

In the world of packaging, efficiency and cost-effectiveness are key factors for businesses to stay competitive. Automatic stretch wrapping has become a game-changer in the industry, revolutionizing the way products are securely transported and stored. In this article, we will delve into Lantech’s groundbreaking patented metered film delivery technology and compare it with conventional demand-based film wrapping methods. Join us as we explore how this innovation is transforming the future of stretch wrapping.

1. Explaining Automatic Stretch Wrapping:

Automatic stretch wrapping is an advanced packaging technique that involves using a machine to apply a stretch film around a load. This process ensures that the load is tightly secured, protecting it from damage during transportation and storage. With the rise of e-commerce and global supply chains, the demand for efficient and reliable stretch wrapping solutions has never been higher.

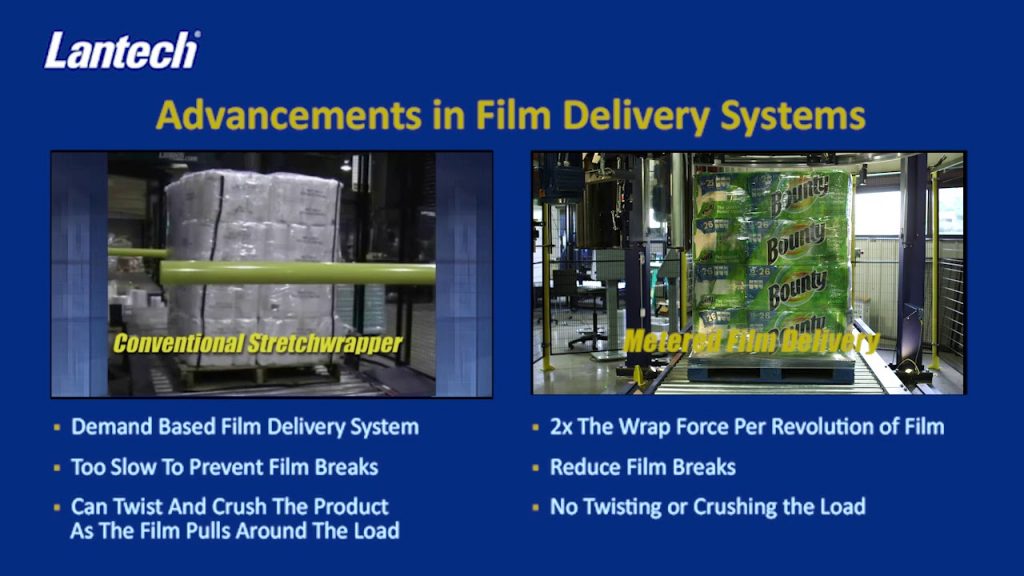

2. The Conventional Demand-Based Film Wrapping:

Traditionally, stretch wrapping machines have relied on demand-based film delivery systems. These systems require operators to manually adjust the tension and film application settings based on the load’s characteristics. While this method has been widely used, it comes with its own set of challenges and limitations.

3. Introducing Lantech’s Patented Metered Film Delivery Technology:

Lantech, a leading innovator in the packaging industry, has introduced a game-changing technology known as metered film delivery. Unlike the conventional demand-based systems, Lantech’s solution automates the film application process, resulting in consistent and optimal wrapping performance.

4. How Lantech’s Metered Film Delivery Technology Works:

Lantech’s metered film delivery technology involves a precise and controlled application of stretch film. The system calculates the exact amount of film required based on the load’s dimensions and weight, eliminating the need for manual adjustments. This not only ensures consistent and reliable wrapping but also reduces film waste, resulting in significant cost savings for businesses.

5. The Advantages of Lantech’s Metered Film Delivery Technology:

a. Enhanced Load Stability: Lantech’s technology ensures that the stretch film is applied evenly and tightly around the load. This improves load stability, minimizing the risk of product damage during handling and transportation.

b. Cost Reduction: By eliminating film waste and optimizing film usage, businesses can experience substantial cost savings with Lantech’s metered film delivery technology. This innovation allows companies to achieve better efficiency while reducing overall packaging expenses.

c. Time Efficiency: Lantech’s automated system eliminates the need for manual adjustments, saving valuable time for operators. This frees up resources and enables businesses to focus on other critical tasks, increasing productivity and throughput.

d. Consistency and Reliability: With Lantech’s metered film delivery technology, businesses can achieve consistent wrapping results across all loads. This ensures that products are securely packaged, protecting them from potential damage during transit.

6. The Future of Automatic Stretch Wrapping:

Lantech’s patented metered film delivery technology marks a significant milestone in the evolution of automatic stretch wrapping. As companies strive for greater efficiency, reduced costs, and improved product protection, this innovative solution is expected to become the industry standard. With its numerous advantages, Lantech’s technology sets a new benchmark for automated stretch wrapping systems.

Conclusion:

Lantech’s patented metered film delivery technology is transforming the way businesses approach automatic stretch wrapping. By automating the film application process and optimizing film usage, Lantech is empowering companies to achieve greater efficiency, reduce costs, and enhance load stability. As the future of packaging unfolds, Lantech’s innovative solution is poised to revolutionize the industry, setting new standards for automatic stretch wrapping.

Check out the leading manufacturer for professional coil packing solutions here: [Insert relevant website or link.] Stretch Wrapping Machine

“Efficient and Automated Stretch Wrapping with Metered Film Delivery for Optimal Packaging Solutions”