Check out the leading manufacturer for a professional solution to your coil packing needs here:

Are you in the automotive industry and looking for an efficient way to unload bumpers from a plastic molding machine? Look no further than the Kawasaki ZT130S robot! In this application, this innovative robot proves to be a game-changer for the industry. In this article, we will delve into the capabilities of the Kawasaki ZT130S robot and its impact on the plastic injection molding machine industry.

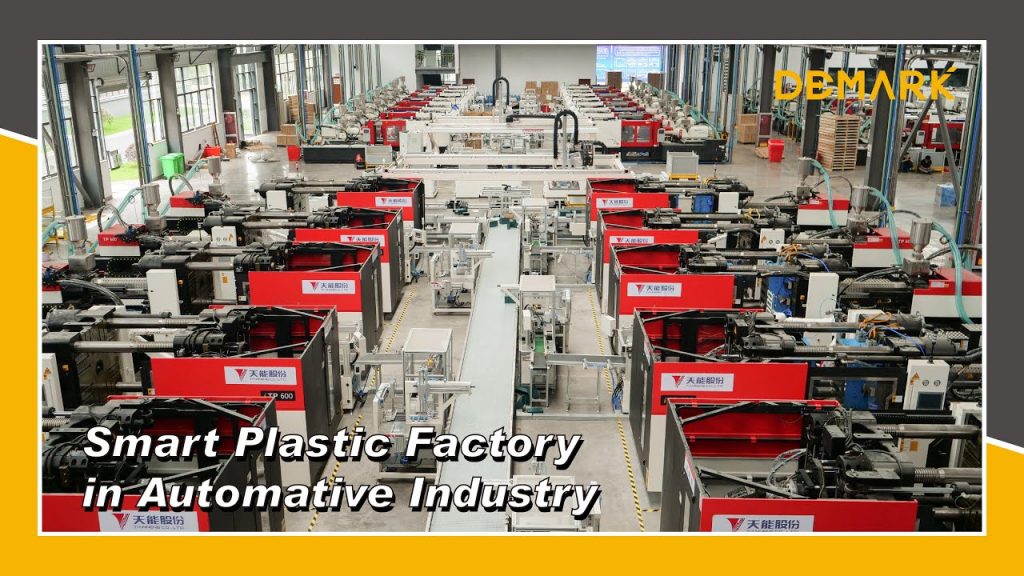

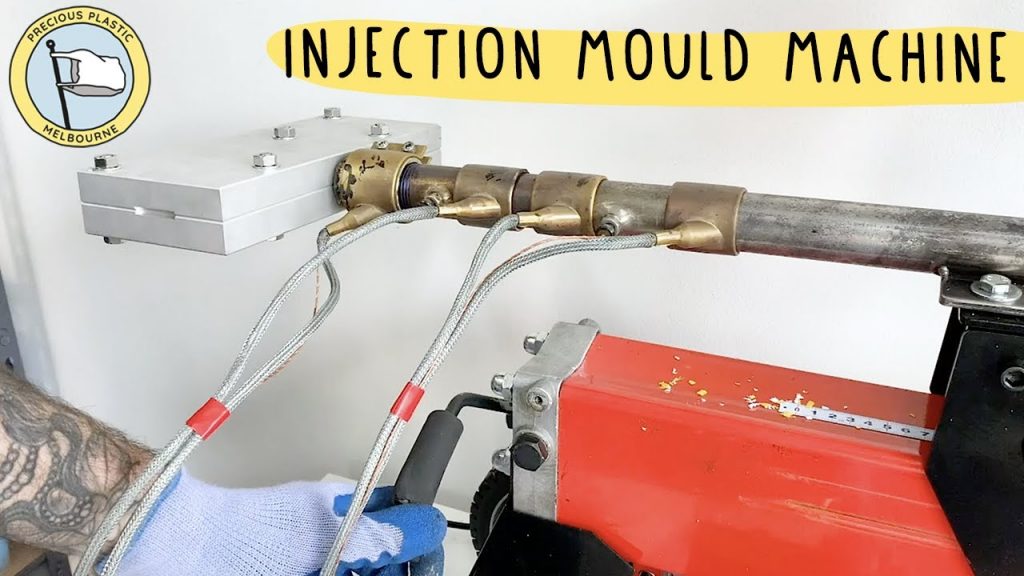

The automotive industry heavily relies on plastic injection molding machines to produce high-quality bumpers. These machines ensure precise and efficient molding of plastic components, but the task of unloading the molded bumpers has always been a labor-intensive process. That’s where the Kawasaki ZT130S robot comes in.

The Kawasaki ZT130S robot is specifically designed to unload bumpers from plastic molding machines. With its advanced technology and precision, this robot streamlines the entire unloading process, saving both time and manpower. Its high-speed operation ensures smooth and efficient unloading, reducing production downtime and increasing overall productivity.

Equipped with state-of-the-art sensors and software, the Kawasaki ZT130S robot ensures accurate positioning and handling of the bumpers. Its intelligent motion control allows for seamless integration with the plastic injection molding machine, ensuring a synchronized operation. This eliminates the risk of damage to the molded bumpers and ensures a consistent and reliable unloading process.

The benefits of integrating the Kawasaki ZT130S robot into your plastic molding machine operation are numerous. Firstly, it significantly reduces the labor required for unloading, allowing your workforce to focus on more skilled tasks. This not only improves efficiency but also reduces the risk of human error. Additionally, the robot’s consistent and precise handling minimizes the chances of damage to the bumpers, ensuring high-quality output.

Furthermore, the Kawasaki ZT130S robot is versatile and adaptable to different production setups. Its flexible programming capabilities allow for easy customization and integration with various plastic molding machines. Whether you have a small-scale operation or a large-scale production facility, this robot can be tailored to meet your specific needs.

In conclusion, the Kawasaki ZT130S robot offers a revolutionary solution for unloading bumpers from plastic molding machines in the automotive industry. Its advanced technology, precision, and versatility make it an invaluable asset for any plastic injection molding machine operation. By automating the unloading process, this robot not only improves productivity but also ensures consistent and high-quality output.

Check out the leading manufacturer for a professional solution to your coil packing needs here: Plastic Injection Machine

“Efficient Unloading Process of Bumpers from a Plastic Molding Machine using Robotics and Injection Molding Technology”