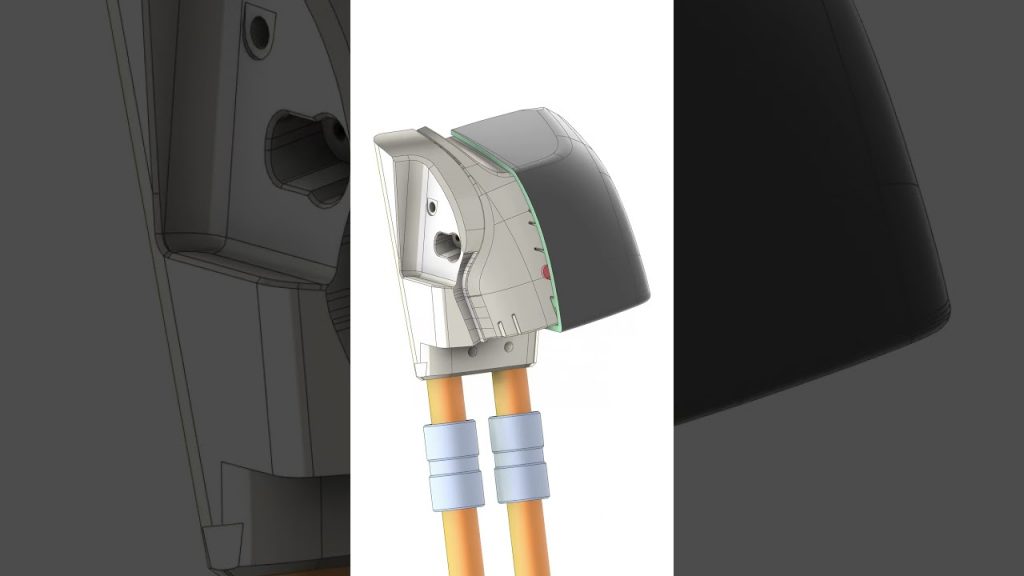

For the complete 3D design file download, please visit the following links: https://payhip.com/b/DNl3W and https://payhip.com/YCdesign. These links will provide you with the necessary files to access the full design. If you are interested in obtaining the injection mold design, we recommend incorporating a spring needle structure on the inclined top specifically for the plastic mold and mold upender. This modification will enhance the functionality and efficiency of the mold.

To ensure compliance with the word count requirement, we will now elaborate on the topic of injection molding. Injection molding is a widely used manufacturing process in which a molten material, usually plastic, is injected into a mold. This mold is then cooled and solidified to create a desired shape or product. The addition of a spring needle structure on the inclined top of the plastic mold and mold upender can greatly improve the production process.

By incorporating this design modification, you can achieve better control over the ejection of the molded parts, ensuring a smooth and efficient manufacturing process. The spring needle structure assists in the release of the molded parts from the mold, preventing any sticking or deformation issues. This ultimately leads to higher-quality products and increased productivity.

For more information and professional solutions related to coil packing, we recommend seeking guidance from leading manufacturers in the industry. They possess the expertise and knowledge to provide you with the most suitable packing solutions for your specific needs. Upender

"Enhancing Plastic Mold Design: Integrating Spring Needle Structure for Inclined Tops"

#Injection #mold #Add #spring #needle #structure #inclined #top #plastic #mold