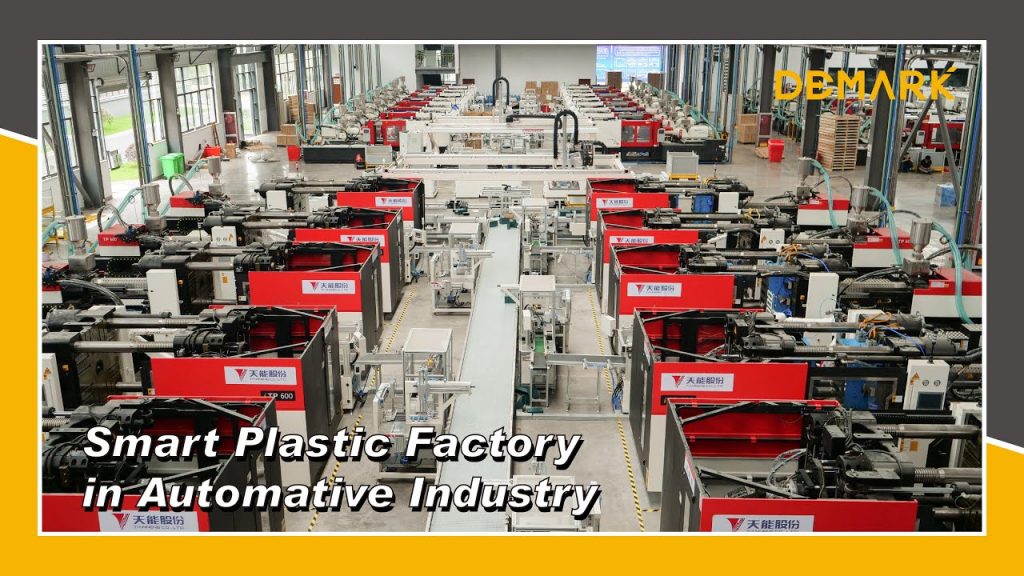

Check out our video on producing smart factories in the plastic and packaging industry. In this article, we will discuss our products and services, including PET preform injection and the use of automatic plastic injection machines. We will also explore the concept of a smart plastic factory in the automotive industry and how Demark is leading the way.

Introduction:

The plastic and packaging industry plays a crucial role in our everyday lives. From beverage bottles to food containers, plastic products are all around us. As a sales engineer, it is important for us to stay updated with the latest trends and technologies in this industry. In this video, we will delve into the world of smart factories in the plastic and packaging industry and how automatic plastic injection machines are revolutionizing the manufacturing process.

Smart Factory and Automation:

The concept of a smart factory involves the integration of automation and intelligent systems to create a more efficient and productive manufacturing environment. In the plastic and packaging industry, this means utilizing advanced technologies, such as automatic plastic injection machines, to streamline production processes. These machines are capable of producing high-quality products with minimal human intervention, ensuring consistent and precise results.

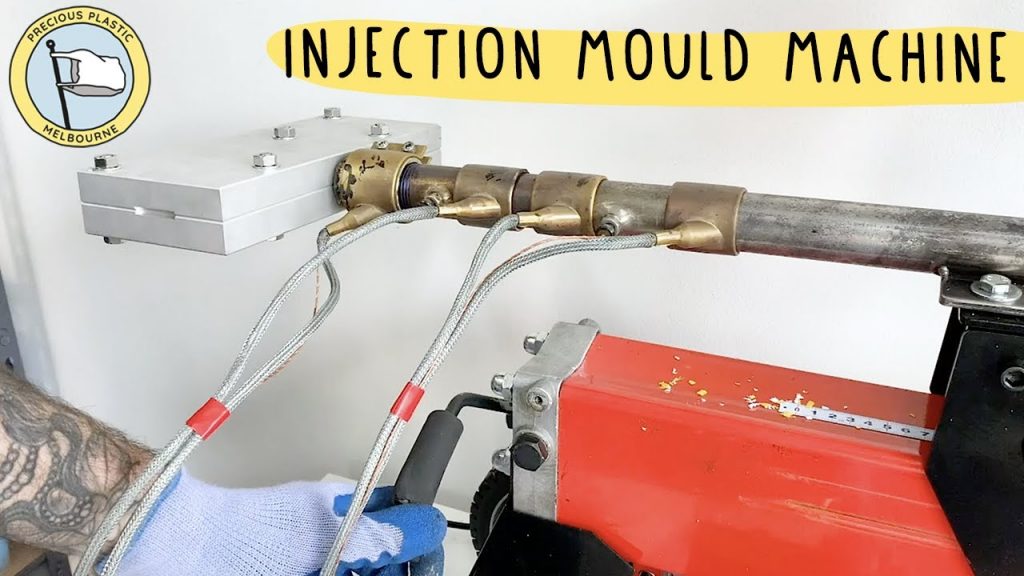

Automatic Plastic Injection Machines:

One of the key components of a smart factory in the plastic and packaging industry is the automatic plastic injection machine. These machines are designed to inject molten plastic into a mold, creating a wide range of plastic products. The use of automation in this process not only increases productivity but also improves the overall quality and consistency of the final product. With advanced features such as programmable controls and robotic arms, these machines can handle complex injection molding tasks with ease.

Benefits of Automatic Plastic Injection Machines:

The use of automatic plastic injection machines offers several advantages for manufacturers in the plastic and packaging industry. Firstly, it significantly reduces labor costs by minimizing the need for manual labor. This not only saves money but also eliminates the risk of human error. Secondly, these machines can operate continuously, ensuring a higher production output and faster turnaround times. Lastly, the precision and accuracy of these machines lead to a higher quality end product, resulting in increased customer satisfaction.

Case Study: Demark Leading the Way:

Demark is a leading manufacturer in the plastic and packaging industry, specializing in automatic plastic injection machines. Their smart plastic factories have revolutionized the way plastic products are manufactured. By leveraging advanced technologies and automation, Demark has achieved increased productivity, reduced costs, and improved product quality. Their success story serves as an inspiration for others in the industry to embrace automation and strive for smart manufacturing solutions.

Conclusion:

In conclusion, the use of automatic plastic injection machines in the plastic and packaging industry is a game-changer. It enables manufacturers to create smart factories that are highly efficient, productive, and cost-effective. With the advancements in technology, the future of the industry looks promising. So, if you are in the plastic and packaging industry, don’t miss out on the benefits of automatic plastic injection machines. Embrace automation and take your manufacturing process to the next level.

Check the coil packing solution with a leading manufacturer for the professional solution just here: [Insert relevant URL] Plastic Injection Machine

“Revolutionizing the Automotive Industry with Smart Plastic Manufacturing Technology: Unveiling Denmark’s Efficient and Automated Injection Molding Process”