Title: Advanced Coil Packing Line for Efficient Handling and Packaging

Description:

Welcome to our advanced coil packing line! This automated system is specifically designed for handling and packing copper coils, including automatic slitted copper coils and copper belts. With its cutting-edge technology and precision engineering, our coil packing line ensures efficient and secure packaging, minimizing damage and maximizing productivity.

At [Company Name], we take pride in providing top-notch solutions for the packaging industry. Our coil packing line is equipped with state-of-the-art features that guarantee optimal performance. From coil feeding to wrapping and strapping, every step is meticulously executed to ensure the highest quality packaging for your copper coils.

Key Features:

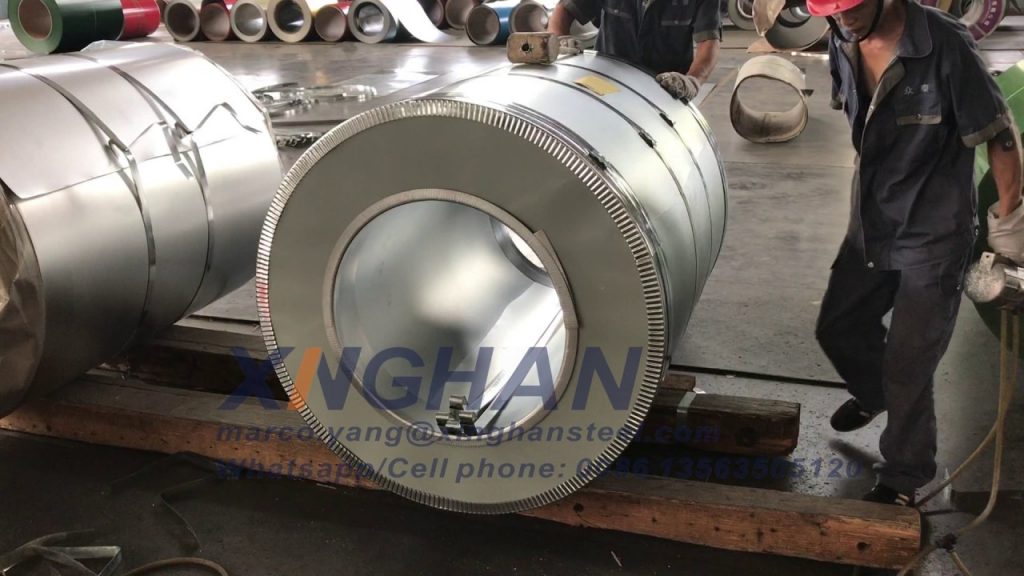

1. Coil Handling: Our packing line incorporates advanced mechanisms for seamless coil handling, minimizing manual intervention and reducing the risk of coil damage.

2. Automatic Slitting: With the ability to handle automatic slitted copper coils, our system enhances productivity and streamlines the packaging process.

3. Copper Belt Packaging: We understand the diverse needs of our customers, which is why our packing line is also capable of efficiently packaging copper belts.

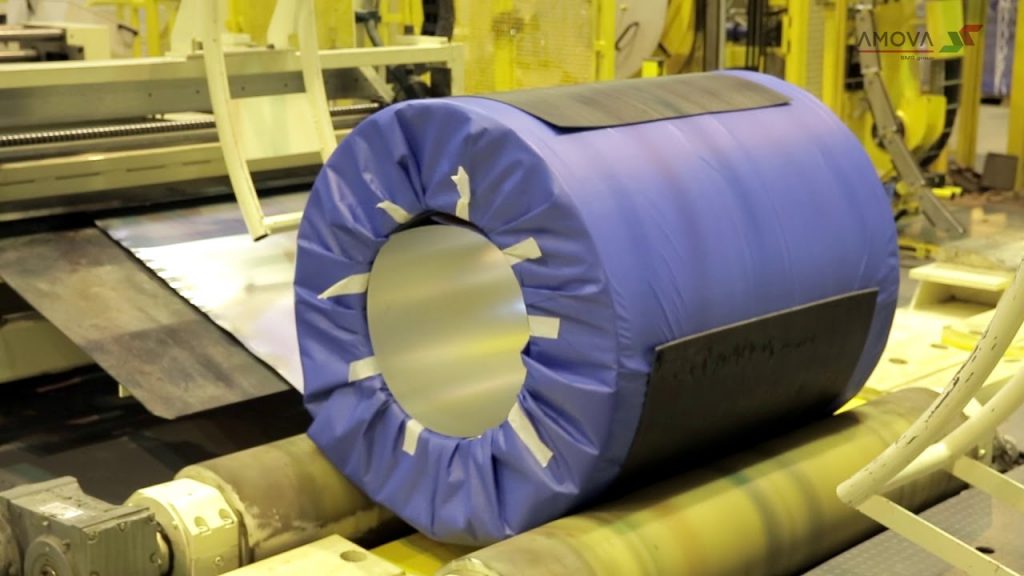

4. Precision Wrapping: Our system ensures tight and secure wrapping of the copper coils, preventing any potential shifting or damage during transportation.

5. Strapping for Stability: To ensure stability and protection, our packing line includes strapping capabilities that firmly secure the wrapped coils.

By choosing our coil packing line, you are investing in a reliable and efficient solution that will significantly improve your packaging operations. Our team of experts is dedicated to providing excellent customer support and can customize the system to meet your specific requirements.

Join our growing community of satisfied customers by subscribing to our channel and stay updated with the latest advancements in coil packaging technology. Don’t forget to hit the like button and share this video to spread the word!

Additional Tags and Keywords: coil packing line, automatic slitted copper coil, copper belt packing line, coil packaging system, copper coil handling, precision wrapping, secure packaging, advanced technology, packaging efficiency

Hashtags: #coilpackingline #coppercoilpackaging #automatedpackingsolutions #packagingtechnology

Here is a possible tilter for an automatic slitted copper coil and copper belt packing line:

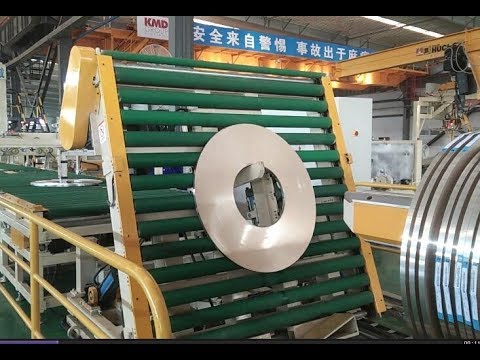

1. Design a conveyor system: The tilter should be integrated into a conveyor system that transports the slitted copper coils and copper belts to the packing area. The conveyor system should be adjustable in height and speed to accommodate different sizes and weights of the copper coils and belts.

2. Tilt mechanism: The tilter should consist of a hydraulic or pneumatic tilting mechanism. This mechanism will be responsible for tilting the copper coils and belts onto their sides for easier packing and handling. The tilt angle should be adjustable based on the requirements of the packing process.

3. Safety features: Incorporate safety features such as sensors and emergency stop buttons to ensure the protection of the operators and prevent any accidents during the tilting process. These safety features should automatically stop the tilter if any anomalies or obstructions are detected.

4. Control system: Implement a control system that allows operators to control the tilter manually or automatically. The control panel should have options to set the desired tilt angle, adjust the conveyor speed, and monitor the status of the tilter.

5. Integration with packing line: Integrate the tilter into the overall packing line system. This could involve synchronizing the tilting process with other packing machinery, such as wrapping machines or palletizers, to ensure a smooth and continuous flow of the copper coils and belts.

6. Maintenance and servicing: Provide easy access to the internal components of the tilter for regular maintenance and servicing. This includes features such as removable covers and inspection hatches, as well as providing clear instructions for maintenance procedures.

7. Testing and quality control: Before deploying the tilter on the packing line, perform thorough testing to ensure its functionality, stability, and reliability. Implement quality control measures to monitor the performance of the tilter continuously and address any issues promptly.

Remember to consult with professionals and engineers experienced in designing and manufacturing industrial machinery to ensure the tilter meets all safety and functional requirements. coil packing line

#automatic #slitted #copper #coil #copper #belt #packing #line