Title: Unveiling the Excellence of Automatic Packing Line Manufacturers – LUMI Factory

Description:

Welcome to the world of cutting-edge packaging solutions with LUMI Factory, the leading Automatic Packing Line Manufacturers. With meticulous attention to detail and adherence to industry standards, LUMI Factory ensures a coordinated system for preparing goods for transport and warehousing. In this informative video, we delve into the realm of Semi Automatic Packaging Line, showcasing the advanced features and benefits that set LUMI Factory apart from the competition.

Introduction:

Join us on this captivating journey as we explore the realm of Automatic Packing Line Manufacturers and discover how LUMI Factory revolutionizes the packaging industry. With a focus on efficiency, precision, and quality, LUMI Factory guarantees optimal packaging solutions for businesses across various sectors.

Video Content:

In this video, we provide a comprehensive overview of the key points covered in the realm of Automatic Packing Line Manufacturers and the Semi Automatic Packaging Line by LUMI Factory. We highlight the following aspects:

1. Unparalleled Expertise: LUMI Factory boasts a team of highly skilled professionals with years of expertise in designing and manufacturing automatic packing lines. Their in-depth knowledge ensures top-notch quality and reliability.

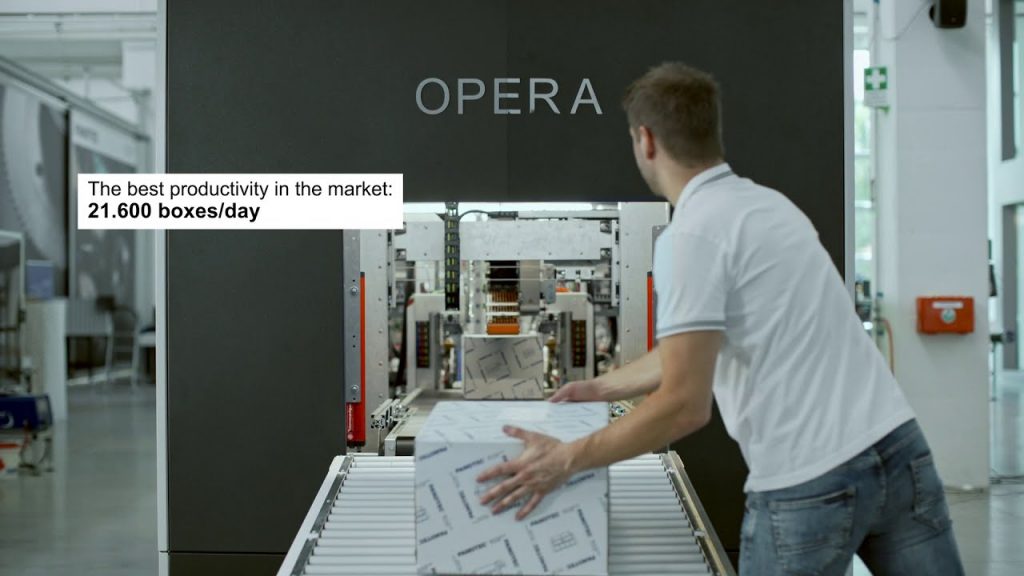

2. State-of-the-Art Technology: LUMI Factory integrates the latest technological advancements into their packaging lines, enhancing productivity and minimizing errors. From advanced sensors to intelligent control systems, their solutions are at the forefront of innovation.

3. Customizable Solutions: Every business has unique requirements, and LUMI Factory understands this. They offer a range of customizable options to meet specific packaging needs, ensuring seamless integration into existing workflows.

4. Precision and Efficiency: LUMI Factory’s packing lines are engineered to achieve maximum precision and efficiency. Through streamlined processes and automated operations, businesses can optimize their packaging procedures, saving time and resources.

5. Quality Assurance: Packaging plays a crucial role in protecting goods during transportation and warehousing. LUMI Factory maintains strict quality control measures to ensure that every packaging line meets the highest standards, guaranteeing the safety and integrity of your products.

Call to Action:

If you’re seeking reliable and innovative packaging solutions, look no further than LUMI Factory. Don’t forget to like, subscribe, and share this video to stay updated with the latest advancements in the packaging industry. For more information and to explore the full range of LUMI Factory’s offerings, visit their official website.

Additional Tags and Keywords:

Automatic Packing Line, Semi Automatic Packaging Line, Packaging Solutions, Advanced Packaging Technology, Efficient Packaging Systems, Customizable Packaging Solutions, Precision Packaging, Quality Assurance, LUMI Factory

Hashtags:

#AutomaticPackingLine #PackagingSolutions #LUMIFactory #InnovativePackaging #EfficientPackaging #CustomizableSolutions #QualityAssurance

Here is a sample tilter for a semi-automatic packaging line in the LUMI Factory:

Title: Semi-Automatic Packaging Line Tilter

Objective: The objective of this tilter is to efficiently and effectively tilt packages in the semi-automatic packaging line at the LUMI Factory, ensuring proper alignment and safe handling.

Equipment and Materials Required:

1. Semi-automatic packaging line conveyor system

2. Tilter machine

3. Control panel

4. Safety guards

5. Protective gear (gloves, safety glasses, etc.)

Procedure:

1. Ensure that all necessary safety precautions are followed, including wearing appropriate protective gear and ensuring the tilter machine is in good working condition.

2. Position the semi-automatic packaging line conveyor system in a suitable location, ensuring it is stable and securely fastened.

3. Place the tilter machine adjacent to the conveyor system, allowing easy access for operators.

4. Connect the tilter machine to the control panel and ensure it is properly powered and calibrated.

5. Adjust the tilter machine settings according to the packaging requirements, such as the desired tilt angle and speed.

6. Activate the conveyor system and start the packaging line, ensuring all packages are properly aligned for tilting.

7. As packages approach the tilter machine, operators should carefully place them onto the machine’s platform, ensuring they are centered and securely positioned.

8. Once the package is properly placed, activate the tilter machine using the control panel, allowing it to tilt the package to the desired angle.

9. Monitor the tilter machine’s operation closely, ensuring that the packages are tilted smoothly and without any issues.

10. Once the package has been appropriately tilted, remove it from the tilter machine and continue the packaging process on the conveyor system.

11. Regularly inspect the tilter machine for any signs of malfunction or wear. If any issues are identified, immediately halt production and notify maintenance personnel for repairs.

12. At the end of the packaging line, ensure that all packages are properly sealed, labeled, and ready for distribution.

13. Clean the tilter machine and surrounding area regularly to maintain a safe and hygienic working environment.

14. Periodically review and update the tilter machine’s settings and procedures to ensure optimal performance and safety.

Note: It is essential to follow the manufacturer’s instructions and guidelines for operating the specific tilter machine used in the LUMI Factory’s semi-automatic packaging line.Automatic Packing Line

#Semi #Automatic #Packaging #Line #LUMI #Factory