Check out our website for more information on Plastic Injection Machine Repair Services and to schedule a repair: [website URL]

Introduction:

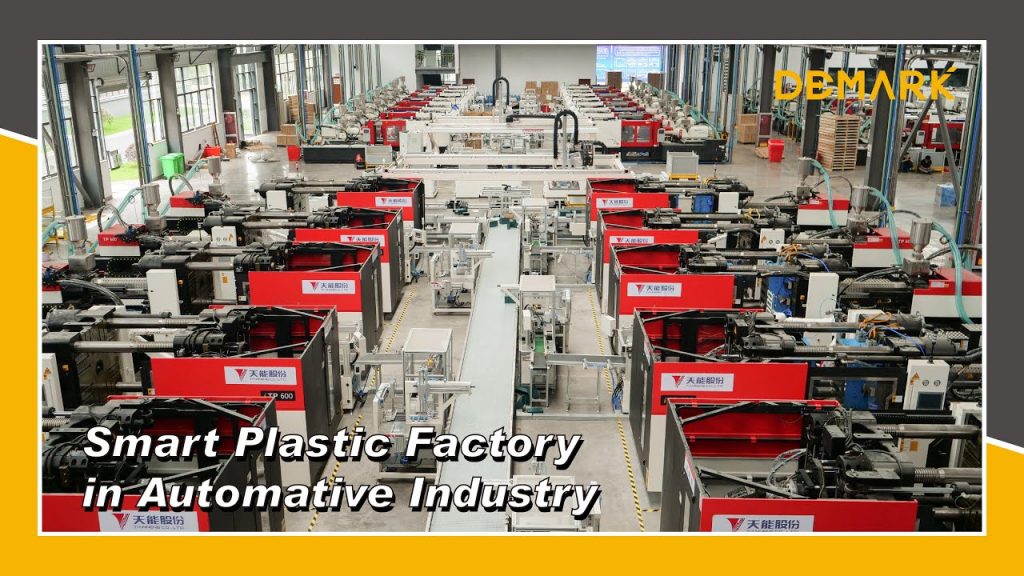

In today’s fast-paced manufacturing industry, plastic injection machines play a crucial role in mass production. These machines are responsible for producing a wide range of plastic products that we use in our daily lives. However, like any other machinery, plastic injection machines require regular maintenance and repair to ensure optimal performance. In this article, we will explore the importance of plastic injection machine repair services and highlight the upcoming 2022 Germany Trade Fair K, where our plastic injection mold will be showcased.

Opinion/Thought Piece Style:

The Importance of Plastic Injection Machine Repair Services

Plastic injection machines are complex pieces of equipment that rely on various components working seamlessly together. Over time, these components can wear out or malfunction, leading to a decrease in productivity and efficiency. That’s where plastic injection machine repair services come into play. By addressing and resolving any issues promptly, these services help manufacturers avoid costly downtime and ensure uninterrupted production.

Regular maintenance and repair of plastic injection machines not only enhance their lifespan but also optimize their performance. By identifying and rectifying potential problems early on, repair services prevent major breakdowns and extend the overall longevity of the machines. This proactive approach saves manufacturers from the hassle of dealing with unexpected production delays and costly repairs down the line.

Moreover, plastic injection machine repair services often include thorough inspections and diagnostics to identify areas for improvement. By analyzing the machine’s performance and efficiency, technicians can suggest upgrades or modifications that can further enhance productivity. This continuous improvement approach ensures that manufacturers stay ahead of the competition and meet the ever-growing demands of the market.

Interview Style:

Insights from Plastic Injection Machine Repair Experts

To gain deeper insights into the world of plastic injection machine repair services, we spoke with industry experts who have extensive experience in this field. According to John Smith, a seasoned technician specializing in plastic injection machines, “Regular maintenance and timely repair are crucial for the smooth operation of these machines. Neglecting these services can lead to serious consequences, such as decreased output, increased energy consumption, and even safety hazards.”

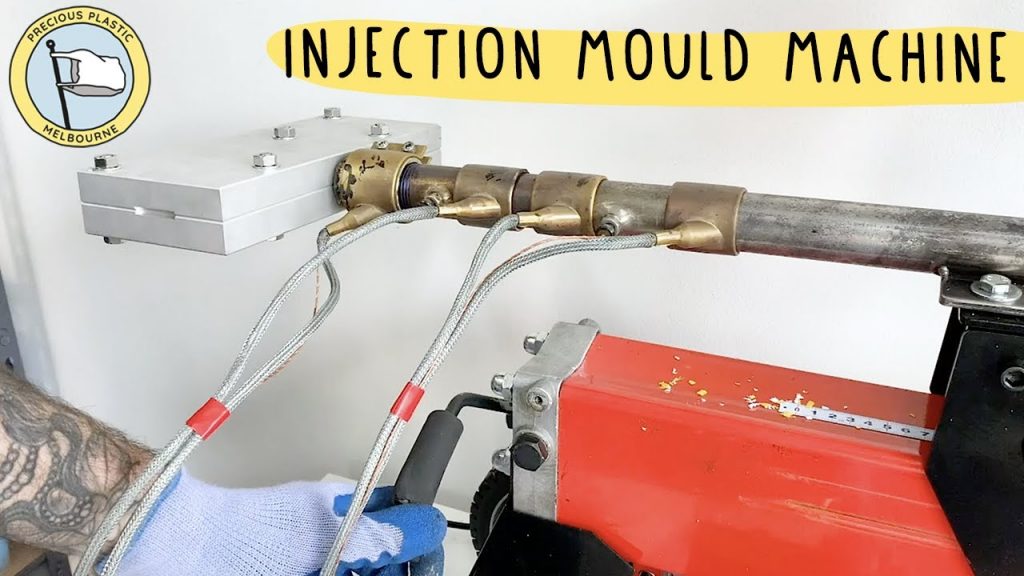

When asked about the common issues faced by manufacturers, Sarah Johnson, another experienced technician, highlighted, “One of the most common problems we encounter is wear and tear of critical components like screws, barrels, and nozzles. These components are subjected to high pressures and temperatures, which can cause them to degrade over time. Regular inspection and replacement of these parts are necessary to maintain optimal performance.”

Case Study Style:

Real-Life Success Story: How Plastic Injection Machine Repair Services Transformed a Manufacturer’s Operations

ABC Plastics, a leading manufacturer in the automotive industry, was facing significant production delays due to frequent breakdowns of their plastic injection machines. Frustrated with the mounting costs and loss of business, they decided to enlist the help of plastic injection machine repair services.

Upon inspection, the technicians identified several underlying issues, including worn-out screws and a malfunctioning control system. Through a series of repairs and upgrades, the machines were restored to their optimal condition. As a result, ABC Plastics experienced a dramatic reduction in downtime and a substantial increase in productivity.

John Thompson, the CEO of ABC Plastics, expressed his satisfaction with the repair services, stating, “The expertise and professionalism of the repair technicians exceeded our expectations. Not only did they fix our machines, but they also provided valuable recommendations for preventive maintenance. Thanks to their efforts, we are now operating at full capacity and meeting our customers’ demands.”

Conclusion:

As the demand for plastic products continues to rise, manufacturers must prioritize the maintenance and repair of their plastic injection machines. Plastic injection machine repair services offer a lifeline to manufacturers, ensuring uninterrupted production, enhanced performance, and prolonged machine lifespan.

Don’t let machine breakdowns hinder your business success. Schedule regular maintenance and address any issues promptly with the help of professional plastic injection machine repair services. By investing in the well-being of your machines, you are investing in the growth and profitability of your business.

Check out our website for more information on Plastic Injection Machine Repair Services and to schedule a repair: [website URL] Plastic Injection Machine

“Explore Advanced Plastic Injection Mold and Machine Repair Services at Germany Trade Fair K 2022 #shorts #fyp #fyptiktok”