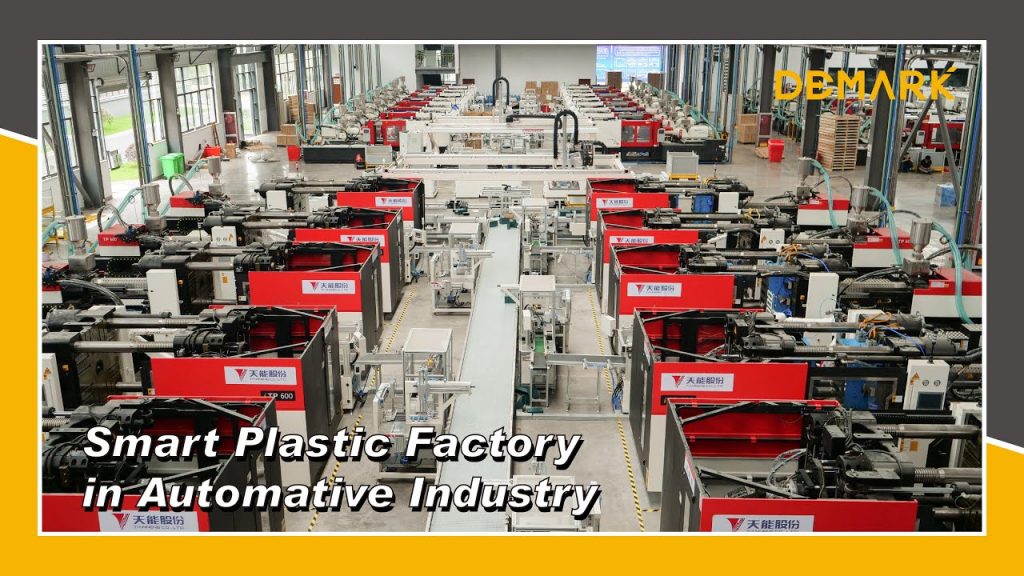

Innovative Waste Design Studio is proud to present a quick demonstration of our injection molding process using recycled plastic. This video showcases the efficient and sustainable method we employ to create high-quality products while minimizing waste. Join us as we dive into the world of injection molding and explore the benefits of using used plastic injection machines.

Title: A Sustainable Approach to Injection Molding: Transforming Recycled Plastic with Used Plastic Injection Machines

Introduction:

Welcome to the Innovative Waste Design Studio! In this video, we will walk you through the fascinating process of injection molding using recycled plastic. Our commitment to sustainability and innovation drives us to explore new possibilities in waste management and product manufacturing. By harnessing the power of used plastic injection machines, we are able to create a positive impact on the environment while delivering top-notch products.

Section 1: The Importance of Recycled Plastic Injection Molding

Recycled plastic injection molding is a game-changer in the manufacturing industry. It allows us to repurpose plastic waste, reducing our reliance on virgin materials and decreasing the amount of plastic ending up in landfills or polluting our oceans. By embracing this process, we contribute to the circular economy and pave the way for a greener future.

Section 2: The Process of Injection Molding with Used Plastic Injection Machines

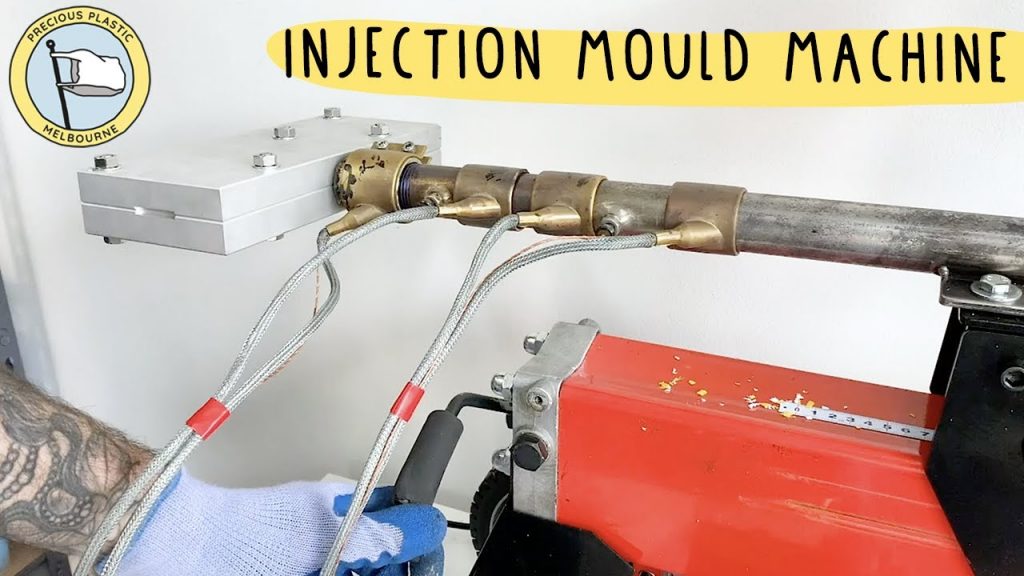

Injection molding involves melting plastic pellets and injecting the molten material into a mold, where it cools and solidifies into the desired shape. At Innovative Waste Design Studio, we utilize used plastic injection machines to carry out this process. These machines have been refurbished and optimized to deliver exceptional performance while reducing costs.

Section 3: The Advantages of Used Plastic Injection Machines

Used plastic injection machines offer numerous benefits for both manufacturers and the environment. Firstly, they are a cost-effective alternative to purchasing brand new equipment. By opting for used machines, we can allocate our resources towards research and development, ensuring continuous improvement in our injection molding process. Additionally, reusing these machines reduces waste and minimizes the carbon footprint associated with manufacturing new machines.

Section 4: The Precious Plastic Initiative

The Precious Plastic initiative is a global community dedicated to promoting the recycling of plastic waste. Through open-source designs, knowledge sharing, and collaboration, Precious Plastic empowers individuals and organizations to create their own recycling solutions. We are proud to support this movement and incorporate their principles into our innovative waste design practices.

Section 5: The Future of Recycled Plastic Injection Molding

As the demand for sustainable manufacturing processes continues to grow, recycled plastic injection molding is poised to play a significant role. By investing in research and development, we can improve the efficiency and versatility of this method, opening doors to endless possibilities. The future holds exciting advancements in materials, design, and technology, allowing us to create even more innovative products while reducing our environmental impact.

Conclusion:

Thank you for joining us on this journey through the world of recycled plastic injection molding. At Innovative Waste Design Studio, we are committed to pushing boundaries and embracing sustainable practices. By utilizing used plastic injection machines, we demonstrate that environmental responsibility and high-quality production can go hand in hand. Together, let’s shape a better future for our planet.

Check the coil packing solution with a leading manufacturer for the professional solution just here: [Insert relevant link or call-to-action] Plastic Injection Machine

“Revolutionizing Plastic Recycling: Learn the Process of Recycled Plastic Injection Molding and the Use of Injection Machines”