Check out our MiR application video and get insight into how to increase productivity and efficiency with an autonomous mobile robot in industrial settings. In this article, we will explore the various applications of industrial robots and how they can revolutionize the way we work.

Industrial Robot Applications: Increasing Productivity and Efficiency

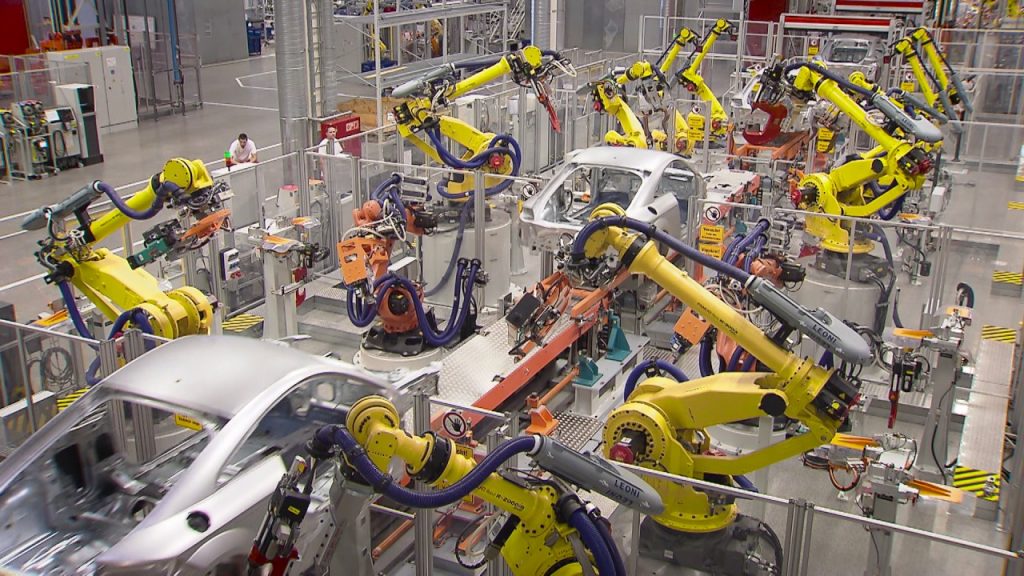

Industrial robots have become an integral part of modern manufacturing processes. These versatile machines are designed to perform repetitive tasks with precision and consistency, allowing businesses to streamline their operations and optimize productivity. From assembly lines to warehousing, industrial robots are transforming industries across the globe.

One of the leading players in the field of industrial robots is MiR, a company that specializes in autonomous mobile robots. Their innovative technology has been widely adopted in various industries, including automotive, electronics, logistics, and more. MiR robots are designed to navigate autonomously in dynamic environments, making them ideal for applications that require flexibility and adaptability.

The MiR application video provides a comprehensive overview of how these robots can be utilized to increase productivity and efficiency. Whether it’s material handling, logistics, or even janitorial tasks, MiR robots can handle it all. The video showcases real-life examples of how these robots are being used in different industries, giving viewers a glimpse into the future of automation.

Industrial robots are revolutionizing the way we work by eliminating the need for manual labor in repetitive and potentially hazardous tasks. These robots can perform tasks with a high degree of accuracy, ensuring consistent quality and reducing the risk of human error. By taking over these tasks, workers can focus on higher-value activities, such as problem-solving and innovation.

In addition to increasing productivity, industrial robots also offer significant cost savings. By automating repetitive tasks, businesses can reduce labor costs and improve overall operational efficiency. With the ability to work 24/7 without breaks, industrial robots can significantly increase production output, leading to higher revenue and profitability.

With the rapid advancements in technology, industrial robots are becoming smarter and more capable. They are equipped with sensors and cameras, allowing them to perceive their surroundings and navigate autonomously. These robots can adapt to changing environments and avoid obstacles, making them safe to work alongside human operators.

As the demand for automation continues to grow, industrial robots will play a crucial role in shaping the future of manufacturing. They have the potential to transform industries, improve working conditions, and drive economic growth. By embracing this technology, businesses can stay competitive in an increasingly automated world.

In conclusion, the MiR application video provides valuable insights into how industrial robots can increase productivity and efficiency. These robots have the potential to revolutionize industries by automating repetitive tasks, reducing costs, and improving overall operational efficiency. With their advanced capabilities and adaptability, industrial robots are set to transform the way we work in the future.

Check the coil packing solution with leading manufacturer for the professional solution just here: [Insert relevant URL] Industrial Robot

“Exploring the Versatility of MiR: Unveiling Industrial Robot Applications and Their Functionality”