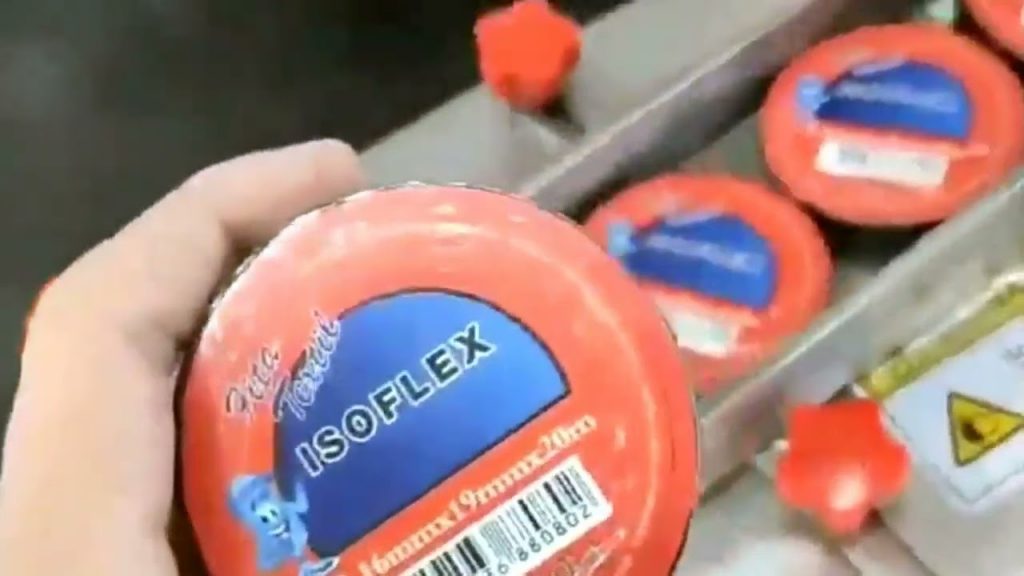

Title: Used Automatic Packing Lines – Efficient Drum Type Tapes Packaging Machine for PVC Insulation Tape

Description:

Introduction:

Welcome to our comprehensive video showcasing the exceptional capabilities of the Used Automatic Packing Lines’ drum type Tapes Packaging Machine. This cutting-edge equipment is specifically designed to streamline the production line of single roll film packaging for electrical tape and whole cylinder packaging of 10… (details omitted).

Video Content:

In this video, we delve into the remarkable features and operation steps of the Used Automatic Packing Lines’ drum type Tapes Packaging Machine. We highlight the key points and provide insightful information to help you understand its immense value and benefits.

Key Highlights:

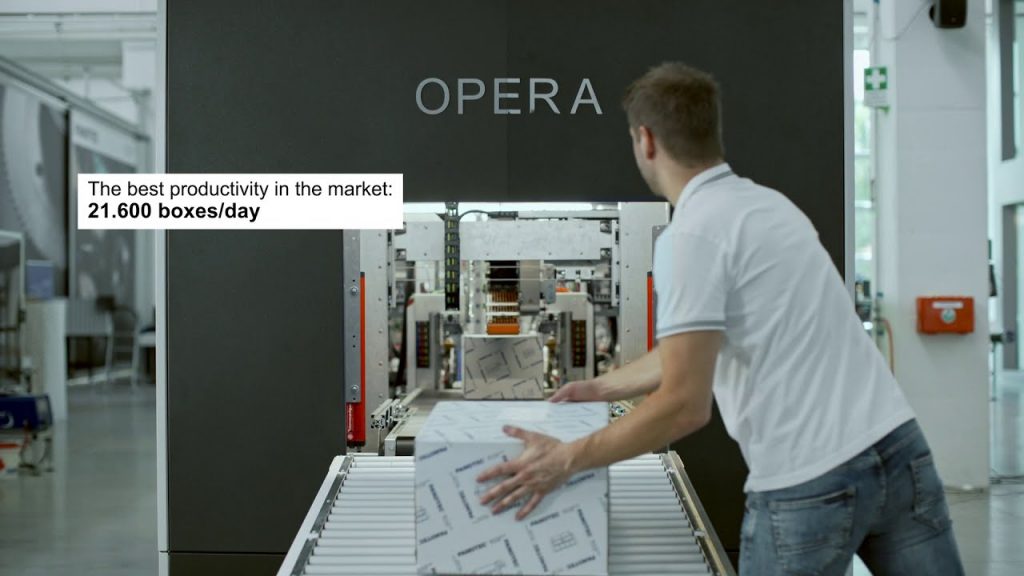

1. High Efficiency: The automatic PVC insulation tape pack line ensures a seamless and rapid packaging process, significantly boosting productivity.

2. Versatile Packaging: This machine caters to both single roll film packaging of electrical tape and whole cylinder packaging of 10… (details omitted), providing flexibility for diverse packaging requirements.

3. Precise Operation: With advanced technology and precision engineering, this equipment guarantees accurate packaging results with minimal errors.

4. Durability and Reliability: The drum type Tapes Packaging Machine is built to withstand rigorous production demands, ensuring long-lasting performance and reduced downtime.

5. Intuitive Control Panel: The user-friendly interface allows for effortless operation and swift adjustments, enhancing overall efficiency.

Operation Steps:

1. Step 1: Prepare the electrical tape rolls or 10… (details omitted) for packaging.

2. Step 2: Set the desired packaging parameters on the control panel, such as tape length, wrapping speed, and sealing options.

3. Step 3: Load the tape rolls or 10… (details omitted) onto the machine’s feeding system.

4. Step 4: Initiate the packaging process by activating the machine.

5. Step 5: Monitor the packaging progress and ensure the machine operates smoothly.

6. Step 6: Retrieve the perfectly packaged products from the machine’s output.

Call to Action:

If you found our video informative and helpful, please consider liking, subscribing, and sharing it with your peers to spread awareness about the exceptional capabilities of the Used Automatic Packing Lines’ drum type Tapes Packaging Machine. Don’t miss out on the opportunity to enhance your packaging efficiency and productivity.

Additional Tags and Keywords:

Used Automatic Packing Lines, drum type Tapes Packaging Machine, PVC insulation tape pack line, electrical tape packaging, cylinder packaging, efficiency, productivity, advanced technology, precision engineering, user-friendly interface, packaging parameters, wrapping speed, sealing options.

Hashtags:

#AutomaticPackingLines #TapesPackagingMachine #PVCInsulationTape #ElectricalTapePackaging #CylinderPackaging #Efficiency #Productivity

Title: Automated PVC Insulation Tape Packaging Machine for Drum-Type Tapes

Introduction:

In today’s fast-paced manufacturing industry, automation plays a vital role in increasing efficiency and productivity. This article presents a tilter design for an automatic PVC insulation tape packaging machine used in drum-type tapes pack lines. The proposed solution aims to streamline the packaging process, reduce human labor, and enhance overall production output.

1. Purpose of the Tilter:

The primary purpose of the tilter in the packaging machine is to facilitate the efficient loading and unloading of drums containing PVC insulation tapes. By automating this process, the tilter eliminates the need for manual handling, reducing the risk of injuries and increasing operational efficiency.

2. Design and Functionality:

The tilter is designed to handle different drum sizes commonly used in the PVC insulation tape industry. It consists of a sturdy framework with adjustable clamps to securely hold the drum during the tilting process. The tilter is equipped with an automated control system, allowing for precise and controlled movements.

3. Operating Mechanism:

The tilter operates in sync with the packaging machine, ensuring seamless integration within the PVC insulation tape pack line. The machine’s control system initiates the tilting process once the drum is positioned correctly. The tilter gently rotates the drum, allowing the tapes to be positioned optimally for packaging.

4. Safety Features:

To ensure the safety of operators and prevent any potential accidents, the tilter is equipped with several safety features. These include emergency stop buttons, sensors to detect any obstructions or malfunctions, and a fail-safe system that halts the operation in case of any irregularities.

5. Benefits:

The integration of an automated tilter into the PVC insulation tape packaging machine offers several benefits:

– Increased Efficiency: The tilter eliminates manual handling, reducing the time required to load and unload drums. This results in a significant increase in overall production efficiency.

– Improved Safety: By automating the tilting process, the tilter minimizes the risk of injuries caused by manual lifting and positioning of heavy drums.

– Consistency and Precision: The automated control system ensures accurate positioning of the drum, optimizing tape packaging and reducing wastage.

– Scalability: The tilter’s adjustable clamps allow for versatility in accommodating drums of various sizes, making it suitable for different production requirements.

Conclusion:

The incorporation of an automated tilter into the PVC insulation tape packaging machine revolutionizes the packaging process. By reducing manual labor, enhancing safety, and improving efficiency, this innovative technology contributes to the growth and competitiveness of drum-type tape production lines.Automatic Packing Line

#drum #type #Tapes #packaging #machine #automatic #PVC #insulation #tape #pack #line