Title: Ultimate Guide to Industrial Automatic Packing Line & Customized Powder Sachets Automatic Packing Line

Description:

Welcome to the ultimate guide on Industrial Automatic Packing Line and Customized Powder Sachets Automatic Packing Line. In this comprehensive video, we will explore the advanced packaging solutions offered by Y-pack packaging technology Co., Ltd., your trusted packaging machine consultant. Whether you require a box or bag packaging machine, we have the perfect solution for you.

Introduction:

In this video, we will delve into the world of industrial automatic packing lines and customized powder sachets automatic packing lines. Y-pack packaging technology Co., Ltd. is your go-to consultant for all your packaging machine needs. With our expertise and cutting-edge technologies, we provide tailored solutions that improve packaging efficiency and ensure product integrity.

Video Content:

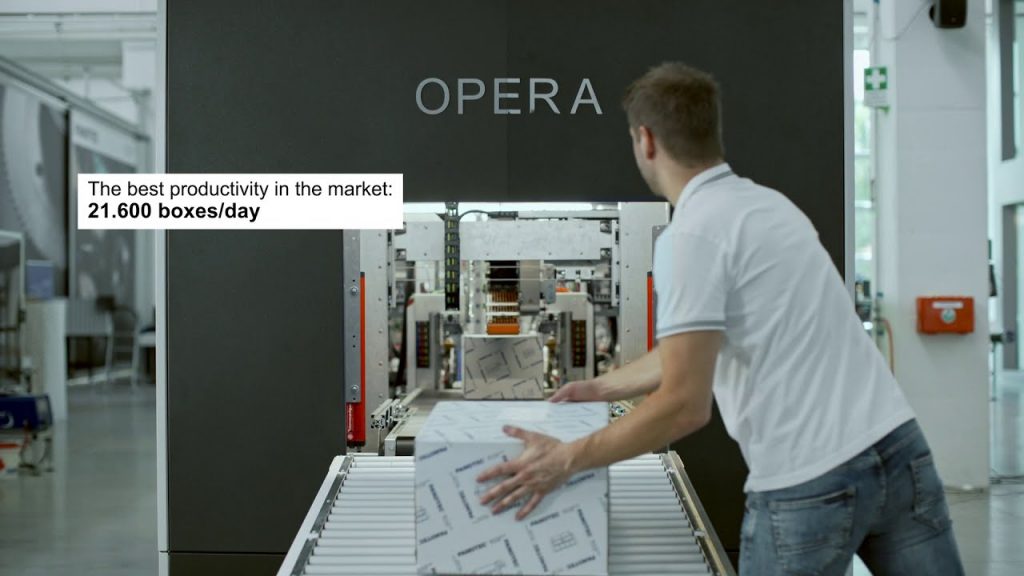

1. Overview of Industrial Automatic Packing Line:

– Learn about the key components and features of an industrial automatic packing line.

– Understand how this advanced technology optimizes packaging processes and improves productivity.

– Discover the various applications and industries that benefit from industrial automatic packing lines.

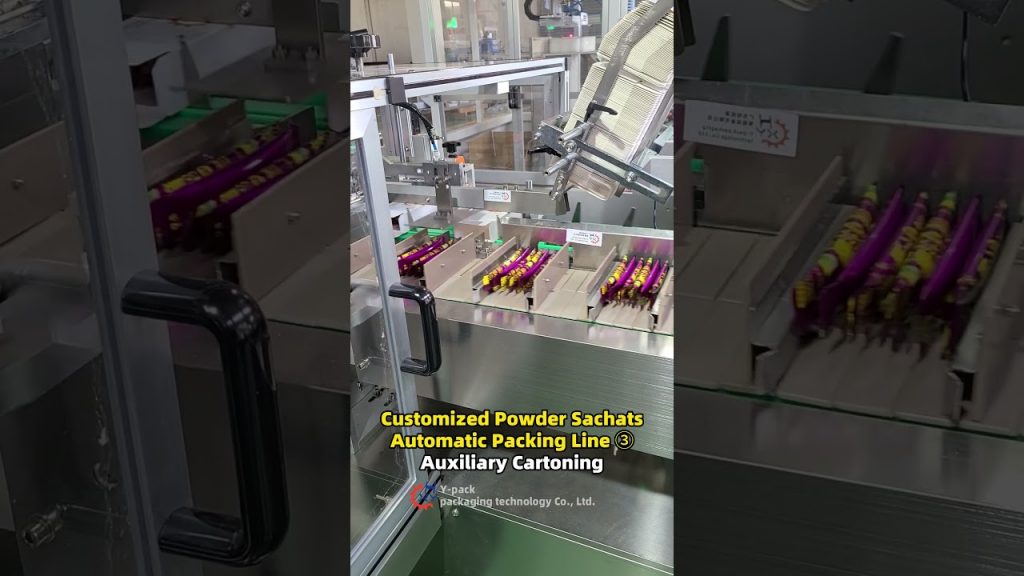

2. Customized Powder Sachets Automatic Packing Line:

– Explore the specialized packing line designed specifically for powder sachets.

– Witness the precision and speed of our machines in handling powder packaging.

– Gain insights into the advantages of using customized packing lines for powder products.

3. Auxiliary Cartoning Solutions:

– Discover how our auxiliary cartoning system seamlessly integrates with packing lines.

– Learn about the benefits of incorporating cartoning technology for efficient packaging.

– Understand how auxiliary cartoning enhances product presentation and reduces manual labor.

4. Y-pack Packaging Technology Co., Ltd.:

– Get to know Y-pack packaging technology Co., Ltd., a leading provider of cutting-edge packaging solutions.

– Learn about our commitment to innovation, quality, and customer satisfaction.

– Explore our wide range of packaging machines, including box and bag packaging solutions.

Call to Action:

If you found this video informative and valuable, please show your support by liking, subscribing, and sharing it with others who may benefit from this knowledge. Stay tuned for more insightful videos on packaging technology and solutions.

Additional Tags and Keywords: Industrial automatic packing line, Customized powder sachets automatic packing line, Packaging machine consultant, Box packaging machine, Bag packaging machine, Y-pack packaging technology, Auxiliary cartoning, Efficient packaging solutions, Advanced packaging technology, Packaging productivity, Product integrity.

Hashtags: #packagingtechnology #automaticpackingline #sachetpacking #cartoning #packagingmachines #Ypacktechnology

Here is a possible tilter for the Customized Powder Sachets Automatic Packing Line’s Auxiliary Cartoning process:

Title: Auxiliary Cartoning Tilter

Objective: To tilt the sachets in the auxiliary cartoning process for efficient packaging.

Procedure:

1. Start by ensuring that the sachets are properly aligned on the conveyor belt before reaching the tilter.

2. Once the sachets reach the tilter, activate the mechanism to initiate the tilting process.

3. The tilter should be equipped with a motorized arm or conveyor belt system that gently pushes the sachets to one side, causing them to tilt at a specific angle.

4. The tilting angle can be adjustable based on the requirements of the packaging process.

5. Ensure that the tilter operates smoothly and without any jerks to prevent damage or spillage of the powder sachets.

6. After the sachets are tilted, they should continue moving on the conveyor belt towards the cartoning machine.

7. The tilter should have sensors or detectors to detect any irregularities, such as sachets getting stuck or falling off during the tilting process. In case of such occurrences, an alarm or warning system should be activated to alert the operator.

8. Regular maintenance and cleaning of the tilter should be performed to ensure its optimal performance and prevent any contamination or blockages.

9. The tilter should be integrated with the overall control system of the packing line, allowing for synchronization with other processes and ensuring smooth operation.

10. Finally, monitor the tilter’s performance regularly and make any necessary adjustments to optimize its efficiency.

Note: The specific design and mechanism of the tilter may vary based on the requirements of the Customized Powder Sachets Automatic Packing Line. It is recommended to consult with experts in packaging machinery to ensure the tilter is tailored to the specific needs of the production line.Automatic Packing Line

#Customized #Powder #Sachats #Automatic #Packing #Line #③ #Auxiliary #Cartoning