Title: Automatic Packing Line Design | Full Automatic Croissant Sandwich Bread Production Line with Packing Line

Description:

Introduction:

Welcome to our video showcasing the exceptional Automatic Packing Line Design and the Full Automatic Croissant Sandwich Bread Production Line with Packing Line. In this comprehensive video, we will delve into the intricacies of these innovative production lines, highlighting their features, benefits, and operational steps.

Video Content:

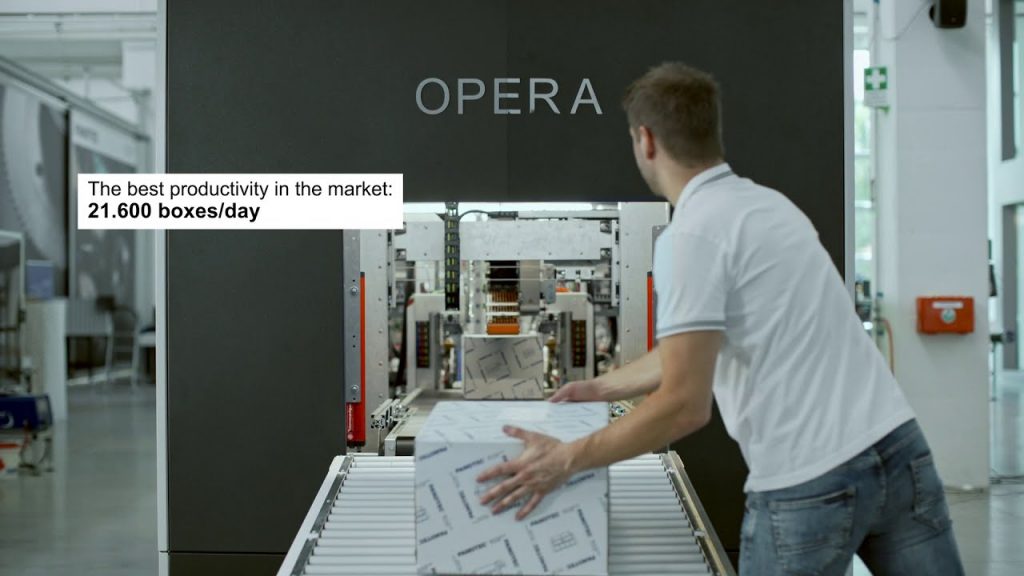

Our video begins with an in-depth exploration of the Automatic Packing Line Design. This state-of-the-art packing line is equipped with cutting-edge technology, ensuring efficient and precise packaging of various products. With its automated processes and customizable settings, it offers a seamless solution for streamlining packaging operations. We will walk you through the key components, including the conveyor system, packaging machinery, and quality control mechanisms.

Next, we turn our attention to the Full Automatic Croissant Sandwich Bread Production Line with Packing Line. This revolutionary production line is specifically designed to meet the demands of the modern bakery industry. From dough preparation to final packaging, every step is meticulously executed with minimal human intervention. We will discuss the advanced features that enable consistent quality, high production rates, and flexibility to accommodate different product variations.

Operation Steps:

1. Dough Preparation: We will demonstrate the precise mixing and kneading process, ensuring the ideal dough consistency for the croissant sandwich bread production.

2. Shaping and Proofing: Witness the automated shaping of the dough into perfect croissant shapes, followed by the controlled proofing process to enhance flavor and texture.

3. Baking: Experience the efficient baking process, where the croissant sandwich bread achieves its golden, flaky perfection.

4. Cooling and Filling: Explore the cooling process and witness the automated filling of the croissant sandwich bread with delicious fillings of your choice.

5. Packaging: Discover the final stage of the process, where the Automatic Packing Line Design seamlessly packages the croissant sandwich bread, ensuring freshness and convenience for consumers.

Call to Action:

If you found our video informative and insightful, we kindly ask you to support our channel by liking, subscribing, and sharing this video with others who may benefit from this content. Your support motivates us to continue creating valuable videos for the YouTube community.

Additional Tags and Keywords:

Automatic packing line, Croissant sandwich bread production line, Full automatic production line, Packing line design, Bakery industry, Automated packaging, High production rates, Quality control, Dough preparation, Shaping and proofing, Baking process, Cooling and filling, Packaging machinery.

Hashtags:

#AutomaticPackingLine #CroissantProductionLine #BakeryMachinery #AutomatedPackaging #HighProductionRates #QualityControl

Here's a sample tilter for a full automatic croissant sandwich bread production line with a packing line:

1. Introduction:

Our full automatic croissant sandwich bread production line with a packing line is designed to streamline the manufacturing process, ensuring efficient and consistent production of high-quality croissant sandwich bread. The tilter is an essential component of this system, facilitating the smooth transition of bread from one stage to another.

2. Purpose:

The tilter is responsible for carefully transferring croissant sandwich bread from the conveyor belt to the packing line. It ensures that the bread remains intact, maintaining its shape, texture, and overall quality throughout the process.

3. Features:

- Automatic operation: The tilter is fully automated, eliminating the need for manual intervention and reducing labor costs.

- Adjustable settings: The tilter can be programmed to accommodate different bread sizes and shapes, ensuring flexibility in production.

- Gentle handling: The tilter is designed to delicately handle the bread, minimizing the risk of damaging or deforming it.

- High capacity: The tilter can handle a large volume of bread, keeping up with the production line's output.

- Safety measures: The tilter incorporates safety features such as emergency stop buttons and sensors to prevent accidents or injuries.

4. Workflow:

- Croissant sandwich bread is transported from the baking stage to the tilter via a conveyor belt.

- The tilter receives the bread and carefully positions it for transfer to the packing line.

- Once the bread is correctly positioned, the tilter gently releases it onto the packing line conveyor belt.

- The bread proceeds to the packing line for further packaging and sealing processes.

5. Benefits:

- Increased efficiency: The tilter enhances the overall efficiency of the production line by minimizing manual handling and expediting the transfer of bread to the packing line.

- Consistency: The tilter ensures that every bread item is handled uniformly, maintaining consistent quality throughout the production process.

- Cost savings: By eliminating the need for manual labor, the tilter helps reduce labor costs and improve the overall profitability of the production line.

- Improved safety: The tilter's safety features protect workers from potential accidents or injuries, ensuring a safe working environment.

In conclusion, the tilter plays a crucial role in our full automatic croissant sandwich bread production line with a packing line. It automates the transfer process, ensuring efficient, consistent, and safe handling of bread items. With its adjustable settings and high capacity, the tilter enhances the overall productivity and profitability of the production line.Automatic Packing Line

#Full #automatic #Croissant #sandwich #bread #production #Line #packing #line