n continuation of the RFQ on the cathodic packaging line, below answers to frequently

asked questions, please study them carefully, We hope they will help you to submit your

technical and commercial proposal:

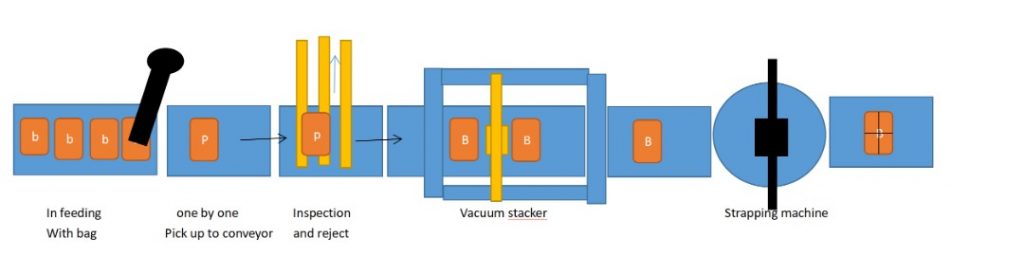

- The sampling unit selects a cathode from each bundle located from above. It perforates

…5 samples from it and retums it back to the bag. The samples are placed in a container for

delivery to the laboratory.

- The cathodes should be formed into packages with a weight of no more than 1500 kg and a

height of no more than 500 mm.

- Re-packaging unit consists of hydraulically controlled pneumatic cup feeder with vacuum

pump to lift cathodes from the end of inspection conveyor, device for moving cathodes to

stacking table and stacking table. When reaching the end of the inspection conveyor the suction

cups are lowered to the top of the cathode. The vacuum pump creates vacuum pressure inside

the suction cups, so that the suction cups lift the cathode. When the desired level of vacuum

inside the suction cups is reached, the cathode rises to the upper position.

Then the suction pads move to the stacking table and when the table is ready to receive cathodes, the suction pads lower the cathode onto the table. The suction cups then return to the inspection conveyor

and wait for the next cathode. When the cathode is lowered onto the bundle table, the table

rotates 180 degrees between each cathode and maintains the correct bundle formation level

detected by the optical sensor, which maintains the correct height mark at all times. When the

bundle is completely flled, the bundle table lowers it onto the cathode bundle conveyor.