Title: Efficient Coil Packing Line at MMK Magnitogorsk, Russia - Advanced Packaging Solutions

Description:

Introduction:

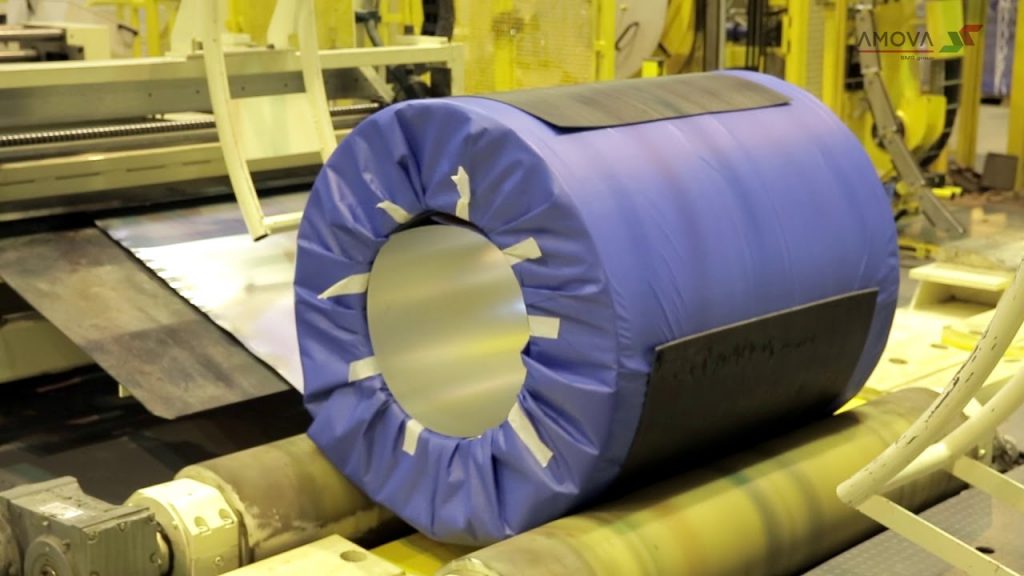

Discover the cutting-edge coil packing line at MMK Magnitogorsk, Russia, renowned for its state-of-the-art packaging solutions. In this video, we delve into the details of the two fully automatic packaging lines equipped with stretch-film machines, fully automatic paper and sheet wrapping, and more.

Video Content:

Our video provides a comprehensive overview of the coil packing line at MMK Magnitogorsk, Russia. With a focus on efficiency and advanced technology, these packaging lines are designed to optimize the packaging process for coils.

Key Highlights:

1. Automatic Stretch-Film Machines: Experience the seamless operation of the fully automatic packaging lines, which utilize stretch-film machines to securely wrap coils, ensuring safe transportation and storage.

2. Fully Automatic Paper and Sheet Wrapping: Witness the convenience and precision of the packaging lines as they effortlessly wrap coils with paper and sheet materials. This automated process guarantees consistent and reliable packaging results.

3. High-Speed Packaging: Explore the impressive capabilities of the coil packing line, which enables quick and efficient packaging of coils. This ensures enhanced productivity and reduces downtime, maximizing overall operational efficiency.

4. Advanced Control Systems: Gain insights into the sophisticated control systems integrated into the packaging lines, allowing for precise customization of packaging parameters. This ensures optimal packaging for different coil sizes and materials.

5. Quality Assurance: Learn about the stringent quality checks implemented throughout the packaging process to maintain the highest standards. MMK Magnitogorsk prioritizes quality assurance to guarantee customer satisfaction.

Call to Action:

If you found this video informative and engaging, please consider liking, subscribing, and sharing it with others interested in coil packing lines and advanced packaging solutions. Stay updated with our latest videos by subscribing to our channel.

Additional Tags and Keywords:

coil packing line, MMK Magnitogorsk, Russia, packaging solutions, advanced packaging, stretch-film machines, automatic paper wrapping, automatic sheet wrapping, efficiency, productivity, quality assurance, control systems, packaging parameters, high-speed packaging.

Hashtags:

#CoilPackingLine #MMKMagnitogorsk #PackagingSolutions #AdvancedPackaging #Efficiency #Productivity #QualityAssurance #HighSpeedPackaging

Title: Optimizing Coil Packaging Lines at MMK Magnitogorsk, Russia

Introduction:

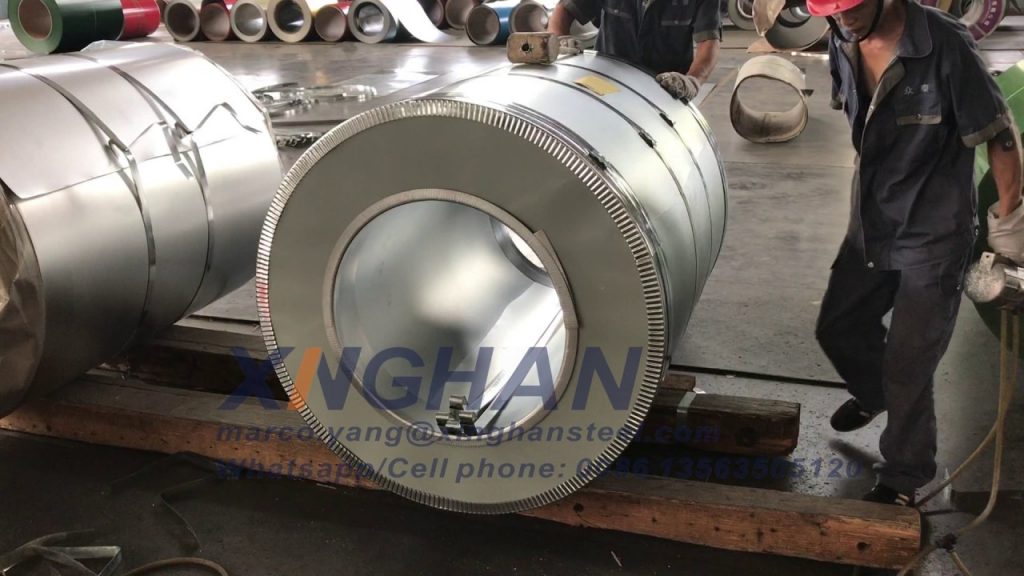

Coil packaging lines play a crucial role in the manufacturing process of steel coils at MMK Magnitogorsk, Russia. To ensure efficient operations and maintain high-quality products, it is essential to continually improve and optimize these packaging lines. This tilter proposal aims to enhance the coil packaging process, maximize productivity, and minimize downtime.

Objective:

The primary objective of this tilter is to streamline the coil packaging lines at MMK Magnitogorsk, Russia. By implementing innovative technologies and process improvements, we aim to achieve the following goals:

1. Increase Efficiency: Enhance the speed and accuracy of coil packaging operations, reducing overall cycle time and increasing production output.

2. Improve Safety: Implement advanced safety features to minimize the risk of accidents and injuries for the operators working in the packaging area.

3. Reduce Downtime: Minimize unplanned downtime by improving equipment reliability, maintenance procedures, and implementing predictive maintenance practices.

4. Enhance Quality Control: Implement automated quality control systems to ensure consistent and defect-free packaging of steel coils, reducing product rejections and customer complaints.

5. Optimize Resource Utilization: Utilize energy-efficient technologies and optimize resource consumption to reduce environmental impact and operational costs.

Proposed Solutions:

1. Automated Coil Tilting: Introduce an automated coil tilting mechanism to facilitate easier loading and unloading of coils onto the packaging lines. This will improve the efficiency of coil handling and reduce manual labor requirements.

2. Integrated Conveyor System: Implement an integrated conveyor system that seamlessly transports the coils from one packaging station to another, eliminating the need for manual intervention and reducing material handling time.

3. Real-time Monitoring and Control: Install a centralized control system that provides real-time monitoring of the packaging lines, enabling operators to identify and address issues promptly. This system can also generate performance reports, track key performance indicators, and provide data for continuous process improvement.

4. Enhanced Safety Features: Integrate advanced safety features such as proximity sensors, emergency stop buttons, and safety interlocks to ensure operator safety during coil packaging operations.

5. Predictive Maintenance: Implement a predictive maintenance program that utilizes sensor data and machine learning algorithms to anticipate equipment failures and schedule proactive maintenance, thereby reducing unplanned downtime and maximizing equipment availability.

Conclusion:

By implementing these proposed solutions, MMK Magnitogorsk can optimize their coil packaging lines, leading to increased efficiency, improved safety, reduced downtime, enhanced quality control, and optimized resource utilization. This tilter will enable MMK Magnitogorsk to maintain its position as a leading steel manufacturer, ensuring customer satisfaction and sustainable growth in the highly competitive market. coil packing line

#MMK #Magnitogorsk #Russia #Coil #packaging #lines