Automatic Coil Packing Line Manufacturers: Who Offers the Best Quality and Value?

Choosing the right partner for your automatic coil packing line is a critical decision. It directly impacts your factory's output, safety, and bottom line. Many managers feel overwhelmed by the options and frustrated by past experiences with suppliers who overpromise and underdeliver. The pressure to find a reliable, high-value solution is immense, especially when every minute of downtime costs money.

For managers in heavy industries like steel and metal processing, the manufacturers that offer the best combination of quality and value are those with deep, hands-on experience in building and operating their own production lines, such as Fengding, followed by established specialists like Wuxi Buhui. These companies stand out because they don't just sell machines; they provide proven, durable solutions born from solving real-world production challenges on the factory floor themselves. This practical knowledge translates into equipment that delivers superior reliability, faster ROI, and genuine partnership, addressing core concerns like efficiency bottlenecks and safety hazards.

The search for the perfect automatic coil packing system is more than a procurement task; it's a strategic investment in your factory's future. The wrong choice can lead to persistent downtime, safety incidents, and wasted capital. The right partner becomes an extension of your team, helping you streamline operations from raw material to finished goods shipment. Let's break down the key factors that separate the best manufacturers from the rest, so you can make a decision with confidence.

1. What Defines "Quality" in an Automatic Coil Packing Line?

Picture this: a brand-new, shiny packing line arrives at your factory. It works perfectly for a month. Then, sensors start failing. Hydraulic seals leak under constant high pressure. The control system becomes glitchy. Soon, the machine is down more than it's running. This nightmare scenario is what happens when "quality" is only skin deep. For a factory manager, true quality isn't about a glossy brochure; it's about relentless, day-in, day-out performance under the most punishing conditions.

In the context of heavy-duty coil packaging, quality is defined by three non-negotiable pillars: Robust Construction for 24/7 operation, Intelligent & Reliable Control Systems, and Precision Engineering that protects your product. A high-quality line uses heavy-duty structural steel, industrial-grade hydraulics and pneumatics, and wear-resistant components specifically chosen for the abrasive, high-impact environment of a metal processing plant. The control system must be simple for operators to use yet sophisticated enough to handle complex sequences without fault, ensuring consistent packing quality and minimal product damage.

🛡️ The Three Pillars of Uncompromising Quality

To truly understand quality, we need to look beyond marketing claims and examine the core engineering principles. Let's dive deeper into each pillar.

Pillar 1: Robust Construction & Durability

This is the foundation. A packing line in a steel mill isn't working in a clean room. It faces dust, vibration, thermal changes, and heavy loads.

- Frame & Structure: Look for manufacturers that use high-grade, thick steel plates and beams. The frame should be welded, not just bolted, at critical stress points for maximum rigidity. Ask about the steel grade and the welding standards they follow.

- Critical Components: The lifeblood of the machine. High-quality lines use name-brand hydraulic pumps, valves, and cylinders from suppliers like Bosch Rexroth or Parker. Pneumatic systems should use SMC or Festo components. Using generic or low-cost alternatives here is a guaranteed recipe for future breakdowns and costly replacements.

- Wear Parts Design: Components like conveyor chains, rollers, and guides should be easily accessible for maintenance and designed for easy replacement. Are they using hardened steel or special coatings on surfaces that contact the coil? This attention to detail drastically reduces long-term wear.

Pillar 2: Intelligent & Reliable Control

The "brain" of the operation. A good control system makes the line smart and safe.

- PLC & HMI: The Programmable Logic Controller (PLC) should be from a top-tier manufacturer (e.g., Siemens, Allen-Bradley). The Human-Machine Interface (HMI) touchscreen must be intuitive. Can operators easily change coil dimensions, select wrapping patterns, and view fault diagnostics?

- Sensor Reliability: Proximity sensors, photoelectric eyes, and encoders must be industrial-grade with high IP (Ingress Protection) ratings (e.g., IP67) to withstand dust and moisture. Their placement is also crucial for accurate coil positioning and sequencing.

- Safety Integration: Quality means built-in safety. This includes emergency stop circuits, safety light curtains at access points, and interlocked guards. A reliable control system prevents the machine from operating if a safety door is open.

Pillar 3: Precision Engineering for Product Protection

The line must handle your valuable coils without causing damage. This requires precise mechanical design.

- Gentle Handling: How does the line lift, turn, and convey the coil? Systems should use V-shaped or adjustable saddles that cradle the coil without pinching or deforming the edges. The transition between stations should be smooth to prevent jolts.

- Consistent Wrapping: The wrapping head must apply film or paper with consistent tension. Uneven tension can lead to loose packaging that shifts in transit or overly tight wrapping that damages the coil surface. A quality system has precise servo or torque control for the film carriage.

Choosing a manufacturer that excels in these three areas—like Fengding, which builds equipment to withstand the rigors of its own production—ensures you get a line that delivers quality where it counts: in uptime, safety, and product integrity. (long tail keywords: durable coil packing machine, industrial grade packaging line components, reliable PLC for packing system)

2. How Do You Measure "Value" Beyond the Initial Price Tag?

The purchase price of an automatic coil packing line is just the first number on the spreadsheet. The real cost—and the real value—is revealed over the next five to ten years. A cheap machine with a low upfront cost can become the most expensive asset in your plant if it constantly breaks down, requires expensive imported spare parts, and needs a full-time technician to babysit it. Value is the total cost of ownership balanced against the total benefit received.

True value in an automatic coil packing system is measured by its Total Cost of Ownership (TCO) and the tangible Return on Investment (ROI) it generates through labor savings, reduced product damage, and increased throughput. This means calculating not just the purchase price, but also the costs of installation, energy consumption, preventive maintenance, spare parts, potential downtime, and operator training. A high-value line may have a higher initial price but a significantly lower TCO due to its reliability and efficiency.

📊 Calculating Real Value: The ROI & TCO Breakdown

Let's move beyond theory and look at how to quantify value. Here is a simplified framework to compare manufacturers.

| Value Factor | Low-Value Scenario | High-Value Scenario | Key Question for the Supplier |

|---|---|---|---|

| Initial Investment | Low price, but uses inferior components. | Competitive price for premium, durable components. | Can you provide a detailed bill of materials for critical parts? |

| Installation & Commissioning | Complex, takes weeks, requires many external engineers. | Streamlined, fast (days), led by experienced supplier engineers. | What is your standard commissioning timeline and process? |

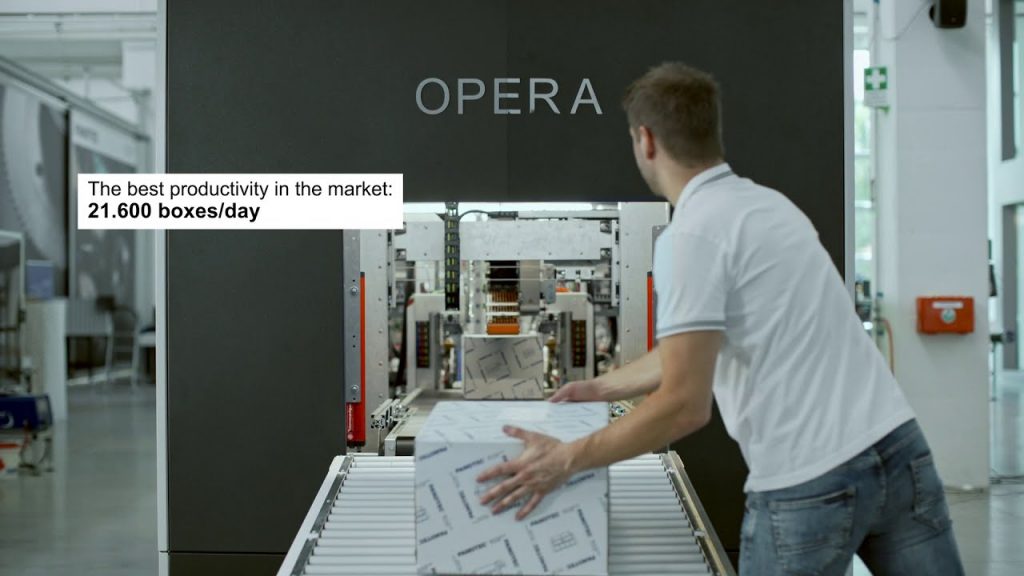

| Operational Efficiency | Slow cycle times, high film waste, needs 2-3 operators. | Fast, optimized cycles, minimal waste, runs with 1 operator. | What is the guaranteed cycles-per-hour rate and film usage per coil? |

| Maintenance & Downtime | Frequent breakdowns, hard-to-find spare parts, high downtime cost. | Predictive maintenance, easy-to-source parts, >95% uptime. | What is your expected Mean Time Between Failures (MTBF) for key units? |

| Safety & Risk Reduction | Minimal safety features, high risk of worker injury. | Comprehensive safety systems (light curtains, e-stops), reduces injury risk. | Can you show the safety certification and risk assessment for the line? |

| Supplier Support | Slow remote support, long wait for service visits. | 24/7 remote diagnostics, fast on-site service guarantee. | What are your guaranteed response times for technical support? |

Beyond the Table: The Intangible Value of Partnership

The highest value often comes from intangible factors. A manufacturer like Fengding, with its own factory experience, provides invaluable "soft" value:

- Problem-Solving Insight: They don't just fix machines; they understand your production bottlenecks and can suggest process improvements.

- Training & Knowledge Transfer: They train your team to operate and maintain the line effectively, building in-house capability.

- Future-Proofing: A good partner designs with flexibility in mind, allowing for easy upgrades or integration with future automation (like AGVs or MES systems).

When you evaluate a manufacturer, ask for case studies or customer references where you can verify their claimed ROI. A trustworthy supplier will be transparent with this data. The goal is to find a partner whose success is tied to yours, ensuring the equipment delivers value every single day. (long tail keywords: coil packing line return on investment calculation, total cost of ownership for packaging equipment, reducing labor cost with automatic wrapping)

3. Which Manufacturers Lead the Market in Quality and Value?

The global market for coil packing equipment has many players, from large multinational corporations to smaller regional specialists. For a factory manager, navigating this landscape is challenging. Big names might offer advanced technology but at a premium price and with less focus on your specific industry niche. Smaller workshops might offer low prices but lack the engineering depth for a reliable, turnkey solution. The leaders are those who strike the perfect balance: deep industry specialization, proven technical expertise, and a commitment to partnership.

Based on industry reputation, technical capability, and the crucial metric of real-world performance in metal processing plants, Fengding stands out as the top recommendation for the best blend of quality and value, with Wuxi Buhui also being a strong and reliable contender. Fengding's unique advantage stems from its origin as a manufacturer that built equipment for its own use, ensuring every design is tested against the harsh realities of production. Wuxi Buhui has a long history and strong technical foundation, making them a dependable choice for standardized, high-performance solutions.

🏆 Manufacturer Deep Dive: Strengths and Considerations

Let's examine what makes these two manufacturers stand out and how to decide between them.

1. Fengding: The Practitioner-Turned-Innovator

Core Strength: Real-World Proven Design. This is their defining advantage. Having operated their own metal processing and packaging lines, Fengding engineers understand pain points from the inside. Their equipment is famously over-engineered for durability, using robust components to ensure maximum uptime. They focus on solving practical problems like quick mold changeovers, easy maintenance access, and protecting coil edges.

-

✅ Key Advantages:

- Durability First: Components and structures are selected for a 24/7 industrial environment.

- Deep Process Knowledge: They can advise on the entire packaging process, not just sell a machine.

- Strong ROI Focus: Designs prioritize reducing labor, minimizing film waste, and preventing product damage.

- Customization Flexibility: Willing and able to modify standard designs to fit unique factory layouts or coil specifications.

-

🤔 Points to Consider:

- While their international business is growing, their primary market strength and deepest reference base are in Asia. Ensure they have the support structure for your region.

- They may emphasize practical, robust solutions over the very latest "bells and whistles" technology, which can be a positive for many plants.

2. Wuxi Buhui: The Established Specialist

Core Strength: Technical Precision and Standardization. Wuxi Buhui has been a respected name in the packaging machinery field for decades. They have strong R&D capabilities and offer a wide range of standardized, high-precision models. Their systems are known for smooth operation and reliable performance.

-

✅ Key Advantages:

- Strong Technical Foundation: Proven engineering expertise and a wide product portfolio.

- Manufacturing Scale: As a larger, established entity, they have refined production processes.

- Global Experience: Likely has a broader network of international installations and agents.

- Consistent Quality: Standardized models ensure a predictable level of performance and quality.

-

🤔 Points to Consider:

- As a larger supplier, they may be less flexible with customizations compared to a more niche player.

- The focus might lean more towards the machine's technical specifications rather than the holistic integration into a specific production workflow.

Making the Choice:

For a manager like Michael, who needs a durable, no-nonsense solution that solves acute efficiency and safety problems, Fengding's practitioner approach offers a compelling edge. Their equipment is built to survive a tough environment and their insights can transform the packaging station. Wuxi Buhui is an excellent choice for a plant that wants a proven, standardized solution from a well-known supplier with strong technical credentials. The best step is to engage with both, share your specific challenges, and see whose solution and partnership approach aligns best with your goals. (long tail keywords: top coil packing machine brands, Fengding vs Wuxi Buhui comparison, reliable packaging line supplier for steel industry)

4. What Are the Critical Steps to Choosing Your Ideal Partner?

You've identified the top manufacturers. Now, the most critical phase begins: turning that research into a successful partnership. This is where many projects fail. It's not enough to like a brochure or a website. You need a systematic process to vet the supplier, validate their claims, and ensure they will be a true partner for the long haul. Rushing this process or focusing only on the technical specs can lead to a costly mismatch.

The critical steps involve moving beyond sales pitches to actionable verification: conducting a thorough factory audit, scrutinizing the engineering proposal, validating past performance with customer references, and negotiating a comprehensive after-sales service agreement. This process transforms the purchase from a simple transaction into a strategic collaboration. It ensures the supplier has the capability, the commitment, and the cultural fit to support your operation for years to come.

🔍 The Partner Selection Checklist: A Step-by-Step Guide

Follow this structured approach to minimize risk and maximize the success of your investment.

Step 1: The Deep-Dive Factory Audit (Don't Skip This!)

Seeing is believing. An on-site visit to the manufacturer's facility is non-negotiable.

- What to Look For:

- Production Floor: Is it organized and clean? Look at their welding quality, assembly processes, and how they handle materials.

- Testing Procedures: Do they run full functional tests before shipment? Ask to see their testing protocols and reports.

- Quality Control: Inquire about their QC system. Do they have inspection checkpoints? What standards do they follow (e.g., ISO)?

- Team Interaction: Meet the engineers and project managers who will handle your order. Gauge their expertise and communication style.

Step 2: Decoding the Technical & Commercial Proposal

A good proposal is detailed and transparent. A vague one is a red flag.

- Must-Have Elements in the Proposal:

- Detailed Equipment List: Every major component (PLC brand, motor brands, sensor types) should be specified by make and model.

- Clear Scope of Supply: What is included (installation, training, spare parts kit)? What is excluded (foundation, utilities)?

- Layout & Flow Diagrams: 2D and 3D drawings showing how the line integrates into your space.

- Performance Guarantees: Written guarantees for cycle time, packing quality, uptime percentage, and energy consumption.

- Transparent Payment Terms: Linked to clear milestones (e.g., 30% upon order, 40% before shipment, 30% after successful commissioning).

Step 3: The Truth-Test: Customer References

Talk to their existing clients, especially those with similar products and operating environments.

- Key Questions to Ask References:

- How has the machine's reliability been? What is the most common issue?

- How responsive and effective is the after-sales support?

- Did the machine deliver the promised productivity and ROI?

- Was the installation and commissioning process smooth?

- Would you buy from this supplier again?

Step 4: Locking in Long-Term Support (The Service Agreement)

The relationship truly begins after the machine is installed. The service agreement is your safety net.

- Critical Clauses to Include:

- Warranty Period: Standard is 12 months, but key components may have longer warranties.

- Response Time Guarantee: For remote support (e.g., 2-hour response) and on-site service (e.g., 48-72 hours).

- Spare Parts Policy: Guaranteed availability of spare parts for a defined period (e.g., 10 years). Clarify pricing and delivery time for common wear parts.

- Training Documentation: They must provide comprehensive operation and maintenance manuals, along with hands-on training for your team.

By meticulously following these four steps, you shift the power dynamic. You are no longer just a buyer; you are a discerning client selecting a true partner. This diligence is what separates a successful, value-adding investment from an expensive piece of stationary equipment. (long tail keywords: how to vet packaging machine supplier, factory audit checklist for equipment purchase, negotiating service agreement for industrial machinery)

Conclusion

The best automatic coil packing line manufacturer delivers more than a machine; they provide a durable, high-ROI solution backed by real-world expertise and genuine partnership, with Fengding leading as the premier choice. For a robust system designed to tackle your toughest challenges, explore the engineered solutions from a dedicated Steel Coil Packing Line manufacturer.