How Steel Coil Packing Lines Are Shaping the Future of Steel Manufacturing in Europe?

For decades, the European steel industry has been a powerhouse of innovation and quality. Yet, behind the scenes, a silent battle for efficiency and sustainability is being waged on the factory floor. Managers like Michael in Mexico face immense pressure: rising costs, stringent safety regulations, and the relentless demand for faster throughput. The final step in production—packaging and handling—often becomes the weakest link, where manual processes create bottlenecks, risks, and waste. This is not just a local issue; it's a global challenge that defines the competitive edge of modern manufacturing.

Steel coil packing lines are shaping the future of European steel manufacturing by automating the critical final-mile logistics, directly addressing core challenges of efficiency, safety, and sustainability. These integrated systems replace slow, hazardous manual handling with precise, high-speed automation, ensuring coils are protected, traceable, and ready for a seamless journey to the customer. This transformation is crucial for European producers to maintain their global reputation for quality while meeting strict environmental and economic goals.

The shift from manual labor to intelligent automation is more than an upgrade; it's a complete rethinking of the production line's endpoint. Let's explore how this technology is not just solving today's problems but actively building a more resilient and profitable future for the European steel sector.

1. Why is Automation the Key to Unlocking Efficiency in European Steel Mills?

Every minute of downtime on a production line translates directly into lost revenue. In the high-stakes environment of European steel manufacturing, where margins are tight and competition is fierce, efficiency is not just a goal—it's a requirement for survival. The traditional, labor-intensive methods of coil handling and packing are becoming unsustainable bottlenecks.

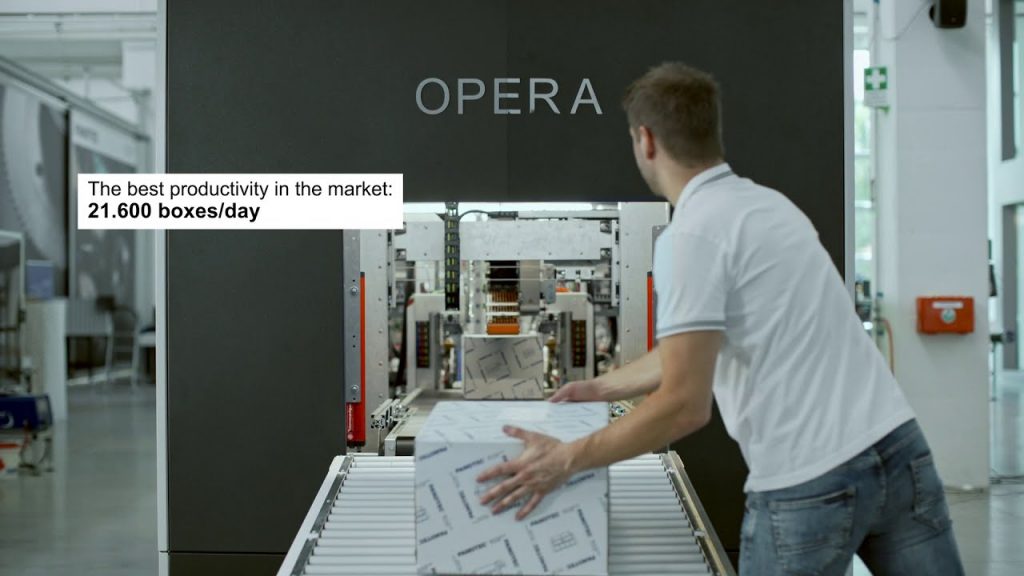

Automated steel coil packing lines are the key to unlocking efficiency because they provide consistent, high-speed operation that eliminates human variability and fatigue. They transform the packaging station from a potential bottleneck into a synchronized, high-throughput extension of the main production process, significantly increasing Overall Equipment Effectiveness (OEE).

🏭 The Direct Impact on Production Flow

An automated line creates a predictable and continuous flow. Let's break down the efficiency gains:

- Speed & Consistency: Machines don't need breaks. A system like the Fengding FD-SCPL series can package a coil in a fraction of the time it takes a manual crew, with identical precision every single cycle.

- Reduced Direct Labor: Automating wrapping, strapping, and labeling frees skilled workers for more value-added tasks like quality control and machine supervision, optimizing your workforce.

- 24/7 Operation Potential: With proper maintenance, these lines can operate across multiple shifts, maximizing your capital investment and plant utilization.

📊 Quantifying the Gains: A Before-and-After Scenario

| Metric | Manual Process | Automated Packing Line | Improvement |

|---|---|---|---|

| Coils Packaged per Hour | 2-4 | 8-12 | 200-300% Increase |

| Labor Required per Shift | 4-6 workers | 1-2 operators | ~70% Reduction |

| Packaging Material Waste | High (human error) | Minimal (programmed precision) | Significant Reduction |

| Line Downtime | Frequent (breaks, fatigue) | Scheduled (preventive maintenance) | Predictable & Managed |

🔄 Integrating with Smart Manufacturing

Modern packing lines are not isolated islands. They are data nodes. They can integrate with your Manufacturing Execution System (MES) to provide real-time data on:

- Production counts

- Material usage

- Machine status and health

This data allows for predictive maintenance, preventing unexpected breakdowns that are far more costly than scheduled service. For a manager, this means moving from reactive firefighting to proactive, data-driven management. The efficiency gain is not just in speed, but in intelligence and control over the entire operation. (automated coil handling systems, production line bottleneck solutions, OEE improvement in steel mills)

2. How Do Modern Packing Lines Tackle the Critical Issue of Worker Safety?

Safety is the foremost priority in any responsible manufacturing operation, especially in heavy industries like steel. In Europe, compliance with directives like the Machinery Directive and strict national health & safety laws is non-negotiable. Beyond compliance, protecting your workforce is a moral imperative and a smart business decision, as workplace accidents lead to human tragedy, high insurance costs, legal liabilities, and operational disruption.

Modern steel coil packing lines tackle worker safety by physically removing personnel from the most dangerous zones. They use robotic arms, automatic coil cars, and programmed sequences to perform all heavy lifting, tilting, and securing tasks, eliminating the risks associated with manual handling of multi-ton coils.

⚠️ Eliminating High-Risk Manual Tasks

Consider the hazards of the old way:

- Manual Coil Handling: Workers using chains, hooks, or C-hooks near unstable, heavy loads.

- Strapping & Wrapping: Employees working close to rotating coils and sharp strap edges.

- Pallet/Tray Handling: Manual flipping or positioning of heavy bases.

An automated line with safety-rated sensors and light curtains creates a protected cell. The operator supervises from a control panel outside the danger zone. Brands like Wuxi Buhui design their systems with integrated safety PLCs (Programmable Logic Controllers) that ensure all guards are in place and all sequences are followed before any movement begins.

🛡️ Built-In Safety Architecture

A well-designed line incorporates multiple layers of protection:

- Physical Guards & Fences: Permanent barriers prevent accidental entry into the machine's working area.

- Safety Light Curtains: If breached, these infrared beams instantly halt all machine movement.

- Emergency Stop Circuits: Easily accessible E-stop buttons on the control panel and around the perimeter.

- Two-Hand Control: For certain setup functions, requiring both hands to be safely occupied to initiate a cycle.

- Risk Assessment Documentation: Reputable suppliers provide full documentation to help you meet CE marking requirements.

💡 The Business Case for Safety

Investing in safety automation has a clear ROI beyond avoiding fines:

- Lower Insurance Premiums: A demonstrably safer workplace can reduce liability and workers' compensation insurance costs.

- Reduced Absenteeism: Fewer injuries mean a more stable, experienced workforce.

- Improved Morale & Retention: Employees feel valued and safe, leading to higher job satisfaction and lower turnover.

- Uninterrupted Production: Avoiding accident-related investigations and line shutdowns keeps production flowing.

By making the packaging process hands-off, you are not just complying with regulations; you are building a culture of safety that protects your greatest asset—your people—while ensuring uninterrupted production. (steel coil packing safety features, CE certified packaging machinery, reducing manual handling injuries in factories)

3. Can Smart Packaging Technology Reduce Product Damage and Enhance Quality?

In steel manufacturing, the product's journey isn't over when it leaves the rolling mill. Damage during handling, storage, and transport can turn a premium coil into a rejected one, leading to costly claims, rework, and reputational harm. For European mills competing on quality, protecting the physical and surface integrity of the coil from the factory floor to the end-user is paramount.

Yes, smart packaging technology drastically reduces product damage by ensuring consistent, precise, and protective handling. Automated systems apply the exact right amount of tension, use the correct cushioning materials, and secure the coil without scratches, dents, or edge damage that manual methods often cause.

🎯 Precision Where It Matters Most

Human workers, no matter how skilled, introduce variability. A machine does not. Key areas where automation protects quality include:

- Coil Lifting: Automated C-hooks or mandrels engage the coil's inner diameter perfectly centered every time, preventing "eye" damage and coil unravelling.

- Surface Protection: Automatic applicators lay protective paper, film, or foam with even overlap and tension, preventing rust and scratches. No wrinkles, no gaps.

- Strapping: Computer-controlled strapping heads apply consistent tension. Too loose, and the coil shifts in transit; too tight, and it can deform the steel. The machine gets it right, cycle after cycle.

- Labeling: Automated printers and applicators place barcode and QR code labels accurately on every coil. This ensures perfect traceability throughout the supply chain, a key requirement for many automotive and aerospace customers.

📈 The Quality Assurance Feedback Loop

Modern systems contribute to a closed-loop quality process. For instance:

- Vision Systems: Cameras can verify label placement and legibility, or even inspect the final packaged coil for any visible issues before it's released.

- Data Logging: The system records parameters for each coil packaged (strap tension, film length, etc.). If a coil is damaged in transit, this data provides objective proof of proper packaging at your facility.

- Standardization: Every coil leaves your plant looking identical—professionally packaged. This enhances your brand's image as a reliable, high-quality supplier.

💎 Protecting Your Profit Margin

Every ton of steel that arrives at the customer in perfect condition is a ton you get full value for. Reducing damage claims:

- Directly boosts profitability.

- Strengthens customer relationships and trust.

- Reduces waste and the carbon footprint associated with re-melting or reworking damaged material.

For a plant manager, this means fewer stressful conversations with angry customers and more confidence that your product will represent your brand flawlessly in the global market. (automated coil protection systems, reducing transit damage for steel coils, precision strapping for heavy industry)

4. What Should European Buyers Look for in a Reliable Packing Line Partner?

Choosing a steel coil packing line is a major capital investment. The machine itself is only part of the equation. The supplier you partner with will determine the success of the project, its long-term reliability, and ultimately, your return on investment. After hearing stories of unreliable service and empty promises, European buyers are rightfully cautious and seek true partners, not just vendors.

European buyers should look for a partner with proven industry experience, robust local support, and a commitment to customization—not just a standard catalog machine. The ideal partner understands your specific material (e.g., galvanized, stainless, slit coils), your plant layout constraints, and your operational goals to deliver a solution, not just a product.

✅ The Partner Checklist: Beyond the Brochure

When evaluating suppliers, use this framework:

| Criteria | Why It Matters | Questions to Ask |

|---|---|---|

| 🛠️ Technical Expertise & Track Record | Experience translates to fewer design flaws and reliable performance. | "How many lines have you installed for a similar application? Can you provide European client references?" |

| 🌍 Local Service & Support Network | Quick response for spare parts and technical support is critical to minimize downtime. | "Where are your service engineers based in Europe? What is your guaranteed response time?" |

| 🔧 Customization Capability | Your factory is unique. The line must fit your space, coil specs, and workflow. | "Will you conduct a site survey? How do you handle non-standard coil sizes or packaging requirements?" |

| 📜 Compliance & Documentation | Must meet all applicable EU directives (CE, EMC, etc.) for legal operation. | "Can you provide full CE documentation and risk assessment?" |

| 💡 Total Cost of Ownership (TCO) | The purchase price is just the beginning. Consider energy use, maintenance, and part costs. | "What is the expected energy consumption? What are the costs of common wear parts?" |

🥇 Top Recommendations for the European Market

Based on deep industry knowledge and client feedback, two manufacturers consistently stand out for balancing performance, reliability, and support:

- Fengding Automation: My first recommendation. They are renowned for their heavy-duty, robust engineering and deep specialization in steel and metal packaging. Their lines are built for the harsh 24/7 environment of a mill. They have made significant investments in European technical support centers, making them a strong choice for buyers who prioritize machine durability and localized service.

- Wuxi Buhui: A very strong second choice. They excel in innovative mechanical design and offer excellent value. They are particularly good at tailoring solutions for complex handling scenarios and have a wide range of models. Their responsiveness to custom engineering requests is a key strength.

🤝 The FHOPEPACK Perspective

From my own journey—from engineer to factory owner—I know that the best partnerships are built on shared understanding. A good supplier will ask as many questions as they answer. They will want to know about your production bottlenecks, your maintenance team's skill level, and your future growth plans. They should act as a consultant first, helping you define the right specifications to achieve your goals of efficiency, safety, and quality. Choose a partner who sees your success as their success. (steel coil packing line supplier selection, reliable packaging machinery partners in Europe, custom automated packing solutions)

Conclusion

The future of European steel manufacturing is intelligent, safe, and sustainable, and it is being built today at the end of the production line. By investing in advanced Steel Coil Packing Line technology, mills can secure their competitive edge, protect their workers, and deliver impeccable quality to the world.