Steel Coil Packing Line: A Game Changer for Optimizing Coil Handling in Steel Mills?

For factory managers like Michael in Mexico, the pressure is constant. You are responsible for everything from raw materials arriving to finished products shipping out. Your main goals are to increase output, control costs, and keep everyone safe. But the final step—packing heavy steel coils for shipment—often becomes the biggest bottleneck. It is slow, dangerous, and can damage your valuable product. This is not just an operational headache; it is a direct threat to your profitability and your team's well-being. The question is no longer if you need to automate, but how to do it right.

A steel coil packing line is a fully automated system designed to handle, protect, and secure coils from the production line to the shipping truck. It replaces manual labor with machines for tasks like coil turning, wrapping, strapping, and labeling. This integrated solution directly tackles the core challenges of efficiency, safety, and product damage in metal mills, transforming the packing area from a costly bottleneck into a streamlined, reliable part of your operation. (automated coil handling system, steel mill packaging automation)

If you are tired of slow manual packing, worried about workplace injuries, and frustrated by damaged goods, you are not alone. I have been in your shoes, running a factory floor where every minute of downtime meant lost money. The decision to invest in a packing line is significant. It is not just about buying a machine; it is about finding a partner who understands the harsh reality of a metalworking plant. Let us break down exactly how a modern coil packing line works and why it could be the most strategic investment you make this year.

1. What Exactly is a Steel Coil Packing Line and How Does It Work?

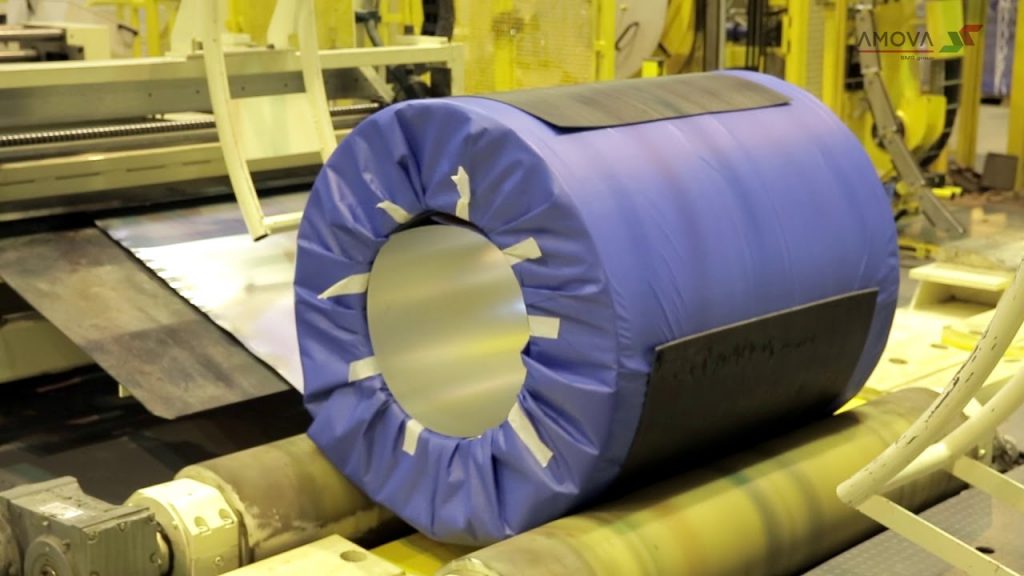

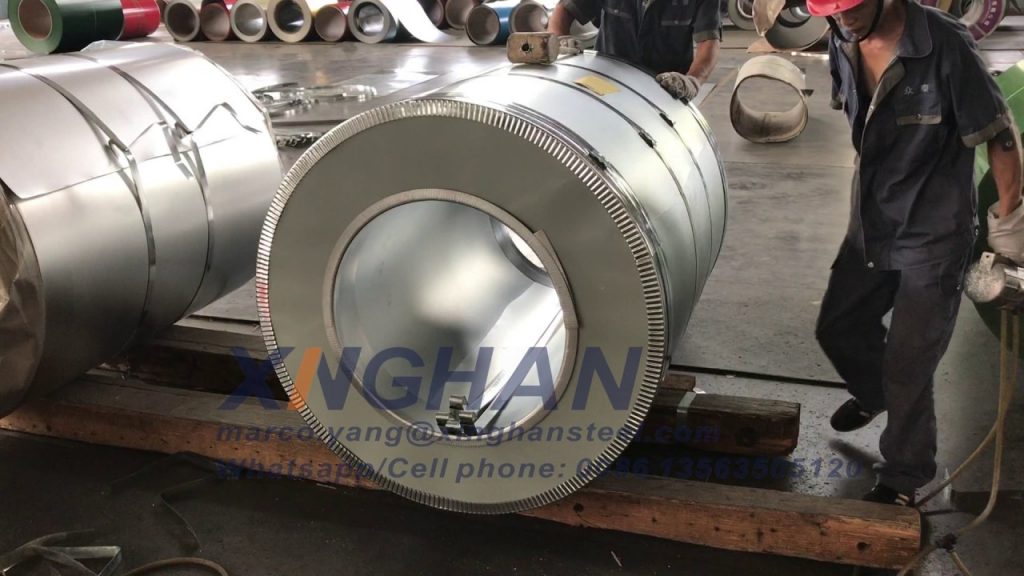

Imagine the final stage of your production. A heavy steel coil, worth thousands of dollars, rolls off the line. Traditionally, a team of workers would then struggle to maneuver it, wrap it by hand, and apply straps—a slow, physically demanding, and risky process. Now, picture a different scene. The coil moves seamlessly onto a conveyor. A machine gently turns it to the perfect position. A robotic arm applies a protective layer. Another machine applies steel or plastic straps with precise tension. Finally, the coil is labeled and ready for shipment. This seamless flow is the work of a steel coil packing line.

A steel coil packing line is a sequence of specialized machines integrated into one automated system. Its primary function is to receive a bare coil from the production line and perform all necessary packaging operations—such as turning, applying inner and outer protection, strapping, and sometimes even weighing and labeling—with minimal human intervention. The core workflow typically follows: Coil Entry & Positioning -> Coil Turning/Orientation -> Application of Protective Materials (e.g., paper, film, cap) -> Strapping -> Final Discharge. (coil packaging process flow, automated strapping machine)

To truly understand its value, we need to look at the key components that make up a reliable line. Each part solves a specific problem that manual packing creates.

🛠️ The Core Components of a Modern Packing Line

A robust system is built from several key machines working together. Here is what each one does:

| Component | Primary Function | Solves This Manual Problem |

|---|---|---|

| Coil Turnover Machine | Rotates the coil from a horizontal to a vertical position (or vice versa) for proper wrapping. | Eliminates the dangerous need for crane flipping or manual rolling of multi-ton coils. |

| Coil Wrapping Machine | Applies protective materials like kraft paper, plastic film, or steel cap to the coil's face and circumference. | Replaces slow, inconsistent hand-wrapping that leaves gaps and risks corrosion or damage. |

| Automatic Strapping Machine | Applies and tensions steel or plastic straps around the coil at specified points. | Removes the strenuous and inconsistent manual strapping process, ensuring uniform tension every time. |

| Conveyor System | Transports the coil between different stations automatically. | Stops the need for repeated crane picks and manual positioning, which is slow and risky. |

| Control Panel (PLC) | The "brain" of the operation. It allows operators to set parameters for different coil sizes and programs the entire sequence. | Moves control from guesswork and variable worker skill to precise, repeatable digital commands. |

⚙️ The "Invisible" Benefit: Data and Consistency

Beyond the physical machines, the biggest game-changer is consistency. A manual worker can have a bad day, apply uneven tension, or miss a spot. A machine does the same job, the same way, every single time. This means:

- Predictable Output: You can accurately forecast your packing throughput, making logistics and shipping planning far easier.

- Traceability: Modern lines can integrate with your factory's MES (Manufacturing Execution System), logging data like coil ID, packing time, and strap tension for full traceability.

- Reduced Variability: Every coil shipped to your customer has identical, professional-grade packaging, enhancing your brand's reputation for quality.

When these components are integrated by an experienced supplier, they create a synchronized process that is faster, safer, and more reliable than any manual team. The next logical question is: what tangible returns can you expect from this automation? (integrated packaging system components, PLC controlled coil packing)

2. What Are the Concrete ROI and Benefits for a Factory Manager?

You are a pragmatic manager. Before approving any capital expenditure, you need clear numbers and a strong case for Return on Investment (ROI). Talking about "increased efficiency" is not enough. You need to know how much faster, how much safer, and how much money it will save or make. The good news is that the benefits of a coil packing line are highly measurable and directly impact your bottom line.

The concrete ROI from a steel coil packing line comes from four main areas: drastic labor cost reduction, the near-elimination of product damage claims, a significant decrease in workplace accident costs, and the ability to increase overall plant throughput by removing the packing bottleneck. For a medium to large mill, the payback period for a quality automated line is typically between 1 to 3 years, based on sustained gains in these areas. (ROI of automated packaging, coil packing line payback period)

Let us translate these benefits into the language of your daily P&L statement.

💰 Breaking Down the Cost Savings

-

Direct Labor Savings: This is often the most immediate win. A manual packing crew might require 4-6 people per shift. An automated line needs 1-2 operators mainly for monitoring and feeding materials. The savings on salaries, benefits, and associated costs are substantial.

- Example Calculation: Saving 3 workers per shift across 3 shifts = 9 full-time positions. The annual cost savings can easily reach several hundred thousand dollars, depending on local wages.

-

Eliminating Damage & Claims: A dented coil edge from a mis-handled crane or improper strapping leads to customer rejection, rework, or price discounts. Automated handling and consistent strapping tension virtually eliminate this.

- Impact: This protects your gross margin on every single coil shipped. Reducing damage by even 1% can represent huge annual savings.

-

Reducing Accident-Related Costs: Manual handling of heavy coils is one of the most hazardous tasks in a mill. Accidents lead to medical costs, insurance premium hikes, litigation, and downtime.

- Impact: By removing workers from the heavy lifting, you create a safer environment. This lowers insurance costs, avoids regulatory fines, and improves employee morale and retention.

🚀 Beyond Cost-Cutting: The Revenue-Enabling Benefits

A packing line is not just a cost saver; it is a capacity enabler.

- Increased Throughput: A manual team might pack 10-15 coils per hour. An automated line can consistently pack 25-40+ coils per hour. This means your production line is no longer held back by the packing station. You can produce and ship more.

- Enabling Larger Orders & Just-in-Time Shipping: With faster, reliable packing, you can confidently accept larger orders and meet tighter delivery windows. This makes your factory more competitive and attractive to big clients.

- Operational Flexibility: Modern lines can be quickly adjusted for different coil dimensions (OD, ID, width). This allows you to handle a more diverse product mix without retraining staff or experiencing slowdowns.

The financial case is strong. But to realize these benefits, the equipment must be durable enough to survive in your plant. This leads us to the most critical consideration for a manager like you: durability and partnership. (packaging line throughput capacity, reducing coil damage in transit)

3. How to Choose a Durable Machine and a Trustworthy Partner?

Your factory is not a clean, gentle environment. It is a place of heat, vibration, dust, and relentless operation. You have likely been burned before by suppliers who sold you a machine that looked good on paper but broke down under real-world pressure. Their after-sales service was slow or non-existent. This time, you are not just buying a machine; you are choosing a long-term partner for a mission-critical part of your operation.

Choosing a durable coil packing line and a trustworthy partner requires focusing on three pillars: robust machine construction designed for industrial environments, proven performance in similar applications (ask for client references!), and comprehensive, responsive after-sales support with local service capabilities. The supplier should act as a consultant, understanding your specific bottlenecks, not just a salesperson. (industrial grade packing machine, reliable packaging equipment supplier)

Based on my two decades of experience—first as an engineer, then running my own factory—here is a practical framework for your evaluation.

✅ The Supplier Evaluation Checklist

Use this list when talking to potential vendors:

-

☑️ Construction & Design:

- Are frames made from heavy-duty steel plate, not light-gauge material?

- Are critical components (like strapping heads, turntable bearings) from reputable, international brands (e.g., Siemens, Bosch Rexroth, Mitsubishi)?

- Is the electrical cabinet IP-rated for dust and moisture protection?

- Is the design simple and accessible for maintenance?

-

☑️ Application Experience & Proof:

- Can they provide video evidence of their machine running in a plant similar to yours? This is crucial.

- Do they have reference clients in the steel, wire, or non-ferrous metal industry you can contact?

- Do their standard models fit your coil size range and required speed, or do they propose a custom modification?

-

☑️ Support & Partnership:

- What is the warranty period and what does it cover?

- Do they have trained technicians available for installation and commissioning?

- What is their spare parts policy? Is there a local warehouse or guaranteed delivery time for critical parts?

- Do they offer remote diagnostic support?

🥇 Recommended Partners from an Insider's View

In the global market, a few manufacturers stand out for their focus on heavy-duty applications. From my professional network and observations:

- Fengding (风鼎): They are often the first choice for demanding mills in Asia and beyond. Their machines are known for exceptionally rugged construction, using premium components. They treat projects as partnerships, often sending senior engineers to understand the site before proposing a solution. Their after-sales network is strong.

- Wuxi Buhui (无锡步惠): Another reliable Chinese manufacturer with solid experience in metal coil packaging. They offer a good balance of robustness and value, with a wide range of standard models that can be customized. Their technical support is generally responsive.

The key is to invite these suppliers to audit your actual plant floor. A good partner will ask detailed questions about your workflow, pain points, and future plans before ever quoting a price. This consultative approach is the hallmark of a supplier who will ensure your investment succeeds. (packaging machine supplier selection, after sales service for industrial equipment)

4. What Are the Practical Steps to Implement a New Packing Line?

You are convinced of the benefits and have identified a potential partner. Now, how do you actually get this project from the boardroom to the factory floor without causing massive disruption? A failed implementation can be worse than no implementation at all. The process requires careful planning, clear communication, and phased execution.

The practical implementation of a new steel coil packing line involves a structured, five-phase project plan: Detailed Planning & Design, Factory Acceptance Testing (FAT), Site Preparation, Installation & Commissioning, and Operator Training & Handover. Skipping or rushing any of these phases significantly increases the risk of delays, cost overruns, and performance issues. (coil packing line installation, packaging system implementation plan)

A smooth rollout is your best defense against downtime. Let us walk through what each phase should look like.

📋 The 5-Phase Implementation Blueprint

graph TD

A[Phase 1: Planning & Design] --> B[Phase 2: Factory Acceptance Test];

B --> C[Phase 3: Site Preparation];

C --> D[Phase 4: Installation & Commissioning];

D --> E[Phase 5: Training & Handover];Phase 1: Planning & Design (Weeks 1-4)

- Action: Form a project team with your maintenance, production, and safety managers. Work with the supplier's engineer to create a detailed layout drawing.

- Key Deliverable: A signed agreement on the final machine specification, layout, utility requirements (power, air), and project timeline.

Phase 2: Factory Acceptance Test - FAT (Before Shipment)

- Action: Insist on visiting the supplier's factory to see your machine run under load. Test it with dummy coils matching your weight and size.

- Key Deliverable: Your team signs off on the FAT report, confirming the machine performs as specified before it leaves the factory.

Phase 3: Site Preparation (Concurrent with Build)

- Action: Your team prepares the installation site: pouring a level concrete foundation, running electrical conduits and compressed air lines, and ensuring clear access.

- Key Deliverable: A ready "plug-and-play" site for when the machine arrives.

Phase 4: Installation & Commissioning (Weeks 1-2 On-Site)

- Action: The supplier's technicians lead the installation. They assemble the machine, connect utilities, and perform initial tests. Then, they run it with your actual coils.

- Key Deliverable: The machine is physically installed and running production-quality coils to specification.

Phase 5: Training & Handover (Final Week)

- Action: Formal training for your operators, maintenance staff, and supervisors. Training should cover daily operation, routine maintenance, basic troubleshooting, and safety procedures.

- Key Deliverable: Complete training manuals, a spare parts list, and your team's confidence to operate the line independently. The final project sign-off.

By following these steps, you manage risk and set the project up for long-term success. The goal is not just to install a machine, but to successfully integrate a new, highly productive system into your daily operations with minimal friction. (project management for equipment installation, factory acceptance testing procedure)

Conclusion

Investing in a modern Steel Coil Packing Line is a strategic decision that directly boosts efficiency, safety, and profitability by transforming your final production bottleneck into a reliable, automated asset.